15.02.2022

Industry 4.0 projects:

Points to consider when developing a digitization initiative

1. Change Management “Growth through change”

Prioritizing the strategic importance of industrial digitization in the company creates the conditions for the sustainable and economic improvement process.

Employees have to be sensitized to the fact that human competence can be better utilized in overarching tasks than for partial tasks. Real-time location technology (RTLS) and the Industrial Internet of Things (IIoT) helps to avoid having to manually perform these partial tasks, such as material identification processes or the systemic input of production & process data. Accordingly, more comprehensive fields of activity are opened up for employees, which results in much higher motivation, since employees evaluate their activities as meaningful and value-adding.

2. Evaluate and assess digitization concepts

In most medium-sized to large companies, resources are available for setting up Smart Factory or Smart Warehouse teams. These often consist of a mix of senior experienced employees and student workers. This is the first time possible concepts are evaluated, assessed and tested. It is important to follow the approach of automating or optimizing functioning and established processes with the help of digitization. Automating a process or workflow that is not running smoothly does not lead to the goal.

This is also the case with our customer Kramer-Werke. In our podcast, the person managing the “Smart Factory” area discusses the key steps required for digitizing wheel loader production, starting with planning and finishing with rollout.

3. Budget and Return on Invest (ROI)

For innovative solutions, such as INTRANAV VIRTUAL Warehouse, SMART Factory and Co., which contribute to an optimization of the processes and use holistic approaches, a case-specific budget must be freed up. Therefore, the first step is to categorize the discovered potential from the research in order to sort it according to priorities. The top -1 potential is evaluated accordingly and, in addition to the allocated budget, internal project resources for implementation, project management and change management must be requested. Always keep in mind the quote from Prof. Dr. Markus Haid “Digital steps are minimal steps”. It points to the problem that companies often try to digitize too much at once. The most successful strategy here is to always roll out the solution step by step – across multiple processes and locations.

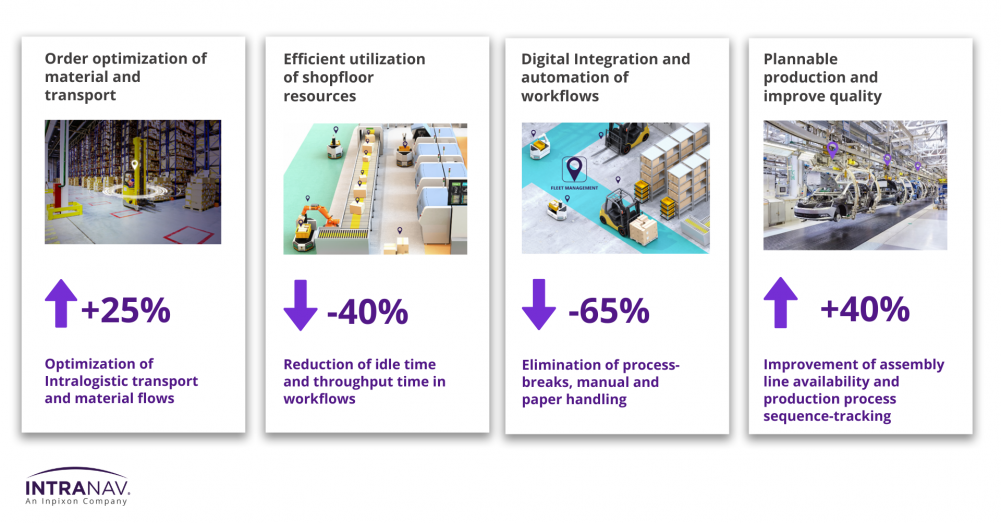

However, after implementation, impressive KPI’s can be quickly achieved, such as up to 40% reduction in idle time and cycle time in workflows, or up to 65% elimination of process interruptions, as well as in manual and paper handling.

More on optimizing transport and material flows with digital end-to-end products from INTRANAV.

4. Define project goals

For the definition of project goals, it helps to ask yourself target-oriented questions in advance. We would be happy to provide a brief explanation using a simple use case example:

● What is our problem / “pain” in inventory management in the warehouse?

o High search times when finding inventory, which stops and slows down the overall process

o System maintenance and management of inventory as a manual process was identified as a “time waster”

o …

● Problem derivation to solution finding: What exactly is to be achieved?

“We want to see the implementation of a cost-effective and multi-site equipment & inventory management system”

● Which processes should be optimized in the inventory warehouse?

o The Inventory Archiving & Registration System is intended to help quickly and specifically find models in the inventory and to enter new objects into the system without any time expenditure

o Mapping of the inventory: real-time overview where the inventory is actually located

o Inventory history, alerts and reminders: we want to track where inventory has been moved to, who has taken it out, and what the actual standing times and storage location capacities are

o Inventory must be recognized in the existing warehouses and at the same time be assignable in the database

● Which software and technologies are suitable for this?

● What steps are necessary to implement the digitization project?

● What infrastructure is required for this?

● Etc.

Learn how an international automotive and motorcycle manufacturer optimized its inventory handling with INTRANAV.IO!

5. Exchange with partners / consultants and testing

After evaluating the problem and the way to solve it, we select appropriate solutions based on modern, investment-safe technologies after exchanging ideas with digitization experts such as INTRANAV or our partners MHP, the management and IT consulting subsidiary of Porsche or umlaut – part of Accenture.

For small to highly complex projects, there are different solutions with modern WMS / ERP, real-time location, RTLS, AutoID, automated vehicles that drive without drivers (so-called AGVs from e.g. Agilox), automated small parts warehouse (AKL) and much more.

However, an important step before implementation is testing! For this purpose, a test meadow must be made available, such as a sandbox for ECOM and test products in the warehouse / at the supplier and 3PL. Here, the projects can be tested for functionality on a small scale and rolled out on a large scale after quality testing.

Author

Ersan Guenes, SVP Product IIoT

Ersan Guenes ist Senior Vice President (SVP) of Product for IIOT (Industrial Internet of Things) at INTRANAV, an Inpixon company.

Learn more about Inpixon