Container Fleet Management: Real-Time Tracking of Load Carriers for Optimized Container Logistics

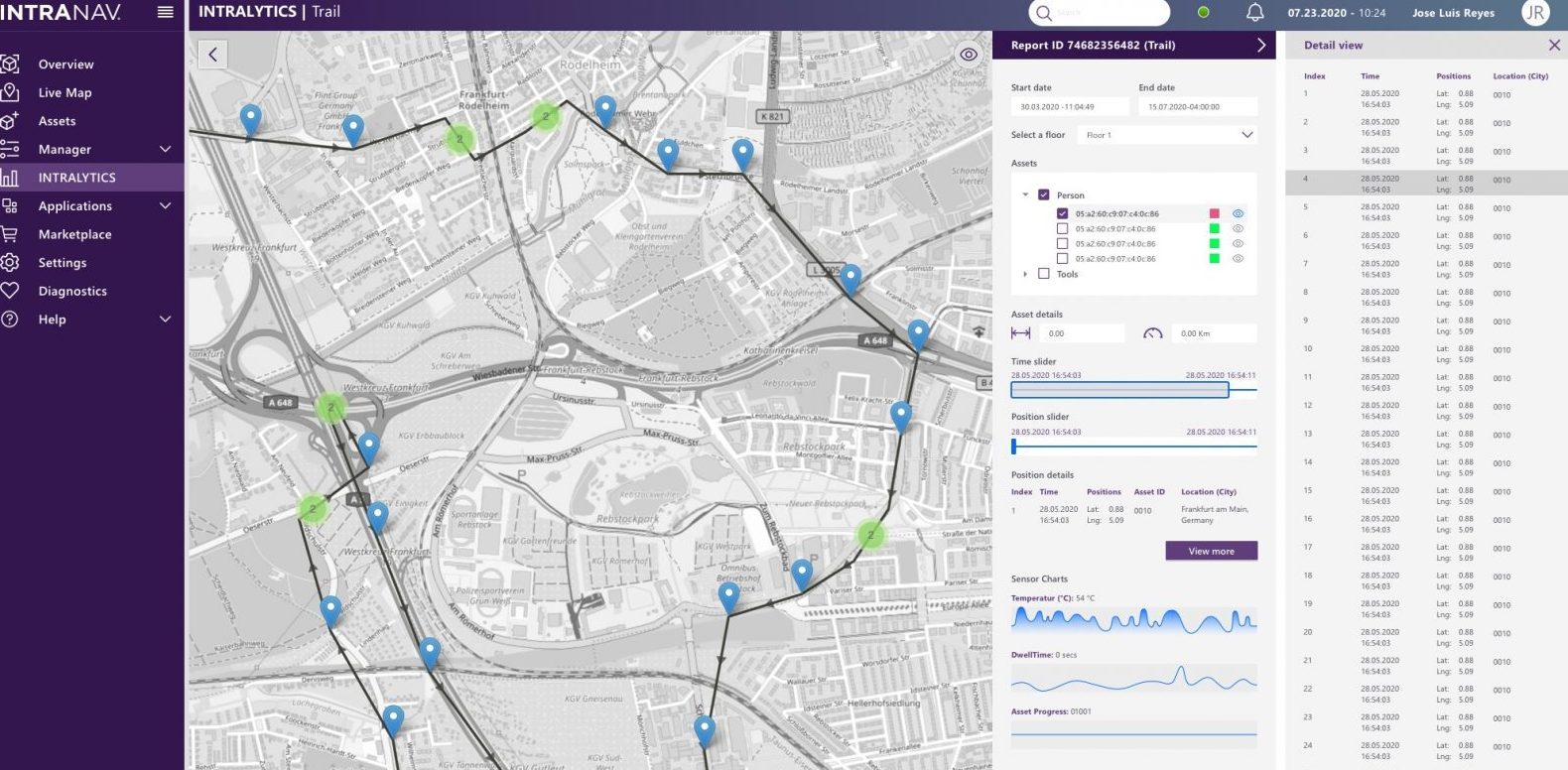

INTRANAV supports container and load carrier tracking with an integrative, independent RTLS IoT suite to enable seamless supply chain visibility across the container fleet and the intralogistic container cycle of small and large load carriers, euro pallets and shipments in real-time. Providing global real-time information through GPS or e.g. Ultra-Wideband (indoor) technology and ERP/WMS API interfaces, the entire container and load carrier flow can be tracked and efficiently controlled. The INTRANAV.RTLS TAGs digitize via Digital Twin and the INTRANAV.IO RTLS platform visualizes the transport flow including live transmission of important information such as geolocation, standing times and makes additional metadata such as customer, article, picking slips retrievable (paperless supply chain), which are necessary for quality control purposes. INTRANAV SMART sensors also monitor temperature, humidity and acceleration/shock of transported goods.

Container automation loops, automatic process triggers, and (e)Kanban material replenishment simplify and accelerate your intralogistics processes. With real-time analytics and clear dashboard reports, you can investigate bottlenecks, utilization or, for example, delivery routes.

The real-time data provides companies within the supply chain with important data on the status of shipments, enabling forwarders to efficiently plan shipping operations, identify shortages and take countermeasures to optimize logistics cycles both immediately and in the long term.