21.01.2021

Real-Time Location Data ermöglicht kosteneffektives und standortübergreifendes Equipment- & Inventar-Management

Für die Herstellung neuer Automobile werden in der Anfangsphase Prototypen entwickelt, diese Modelle (bestehen beispielsweise aus Lehm, Schaumstoff, Hartkunststoff, 3-D Drucken und) werden anschließend für Design-Studien verwendet, um fortführend am Modell zu arbeiten oder weitere neue Produktmodelle zu entwickeln. Dieses Inventar wird von unserem Kunden, einem internationalen Automobilhersteller, in einem Warehouse Management System erfasst und archiviert. Dieser beschloss im Zuge seiner Digitalisierungsstrategie, sein altes Inventar Management für Fahrzeugprototypen und Showcars abzulösen, um es standortübergreifend mit der Real-Time Location System Plattform Lösung von INTRANAV neu auszurichten.

Für einen internationalen Automobil-

und Motorradhersteller

Unser Kunde ist ein börsennotierter, international operierender Automobil- und Motorradhersteller mit Sitz in Deutschland. Die Produktpalette des Premiumherstellers umfasst hochpreisige, komfortabel ausgestattete und hervorragend motorisierte Fahrzeuge mit sportlichem Anspruch.

Anforderungen unseres Kunden

-

1

Digital Twin des gesamten Prototyp-Inventars sowie eine erweiterbare Modelldatenbank

Echtzeit-Übersicht wo sich das Inventar tatsächlich befindet, dank Real-Time Location Daten. Das hochskalierbare und flexible INTRANAV IoT System kann zehntausende bis zu Millionen von Bauteilen, Modellen, Prototypen und Objekten verwalten.

-

2

Inventarhistorie, Alerts & Reminder

Smartes Inventar-Management: Wohin wurden die Modelle bewegt, wer hat sie entnommen, wie sind die Standzeiten und Lagerstandortkapazitäten. Warnungen und Erinnerungen, falls Modelle an den falschen Orten stehen/abgelegt werden.

-

3

Automatische Bauteileerfassung

INTRANAV muss alle Bauteile in den existierenden Lagerhallen erkennen und gleichzeitig in der Datenbank zuordnen.

Lösung von INTRANAV

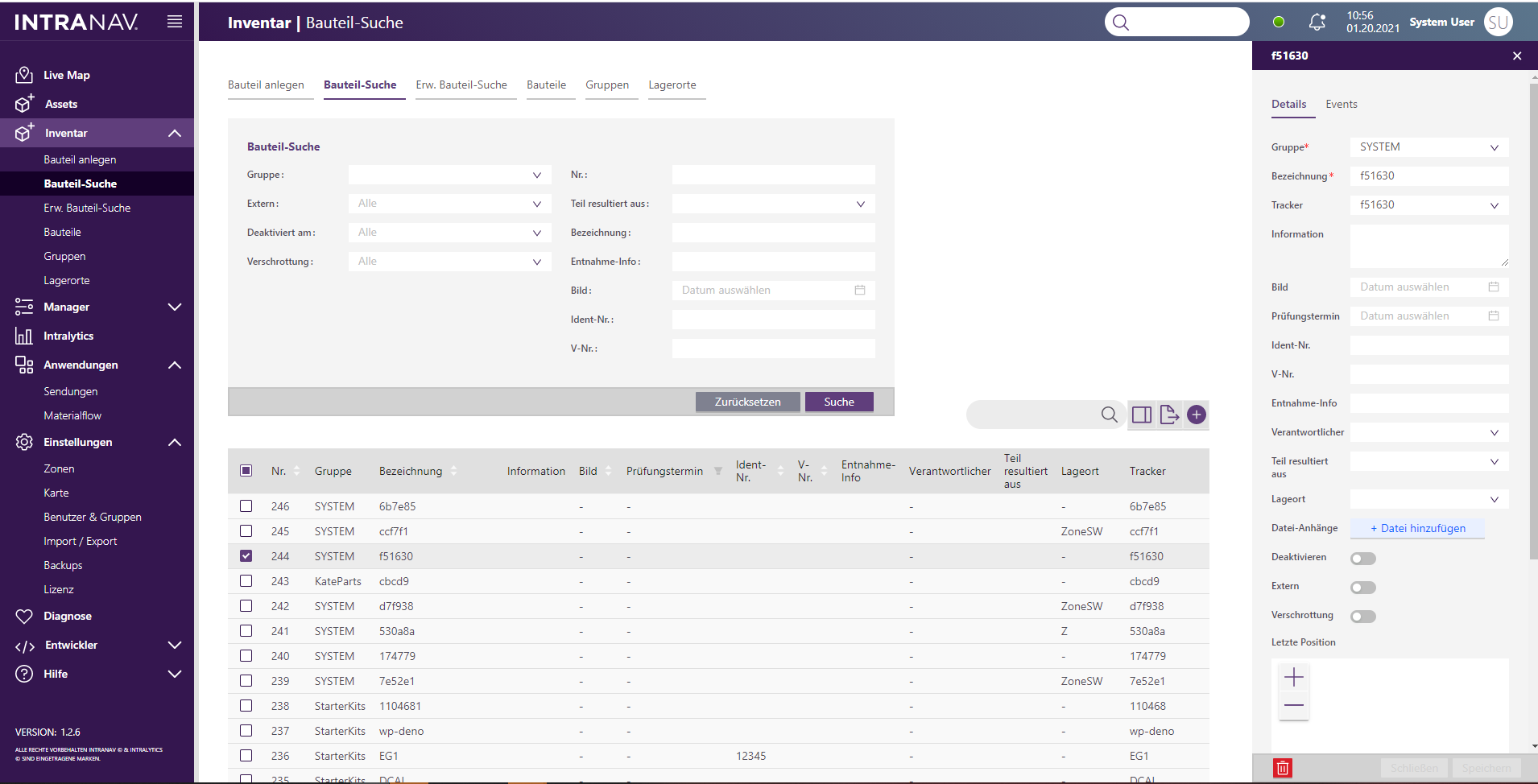

Das neuartige Modelarchivierungs- & Modelerfassungssystem soll dazu beitragen schnell und gezielt Modelle im Bestand aufzufinden und neue Modelle in das System einzupflegen. Die INTRANAV.IO RTLS Plattform läuft auf der Cloud des Automotive Kunden und ist eine moderne Software, die auf den neuesten Web-Technologien basiert. Alle oben genannten Anforderung können über die Digital Twin Plattform abgerufen, getrackt, organisiert und analysiert werden.

Weitere hilfreiche Features sind; das Eintragen von zusätzlichen Informationen (Meta-Daten, Flags) und Dateianhängen pro Inventar-Objekt, sowie Hinweise und Markierungen wie „Verschrottung“ oder „Objekt ausgeliehen für Messen und Events“. Zudem ermöglichen kundenspezifische Rechte und Rollenmodelle eine einfache Nutzerverwaltung. Eigene Gruppen können sehr flexibel erstellt werden oder auch Parameter und Nummernkreise hinzugefügt werden. Durch die Suchleiste ist eine sehr schnelle Auffindbarkeit und erweiterbare Suchfunktion möglich. Das INTRANAV IoT System nutzt das „Single-Sign-On“ (SSO) für maximalen Komfort für den Kunden, wobei sich Nutzer mit ihren bestehenden Daten einloggen. Im Modellager Management kommt es auf eine kosteneffektive, kabellose Real-Time Tracking Lösung an, bei der eine Ortungsgenauigkeit von 1 bis 3 Metern ausreicht.

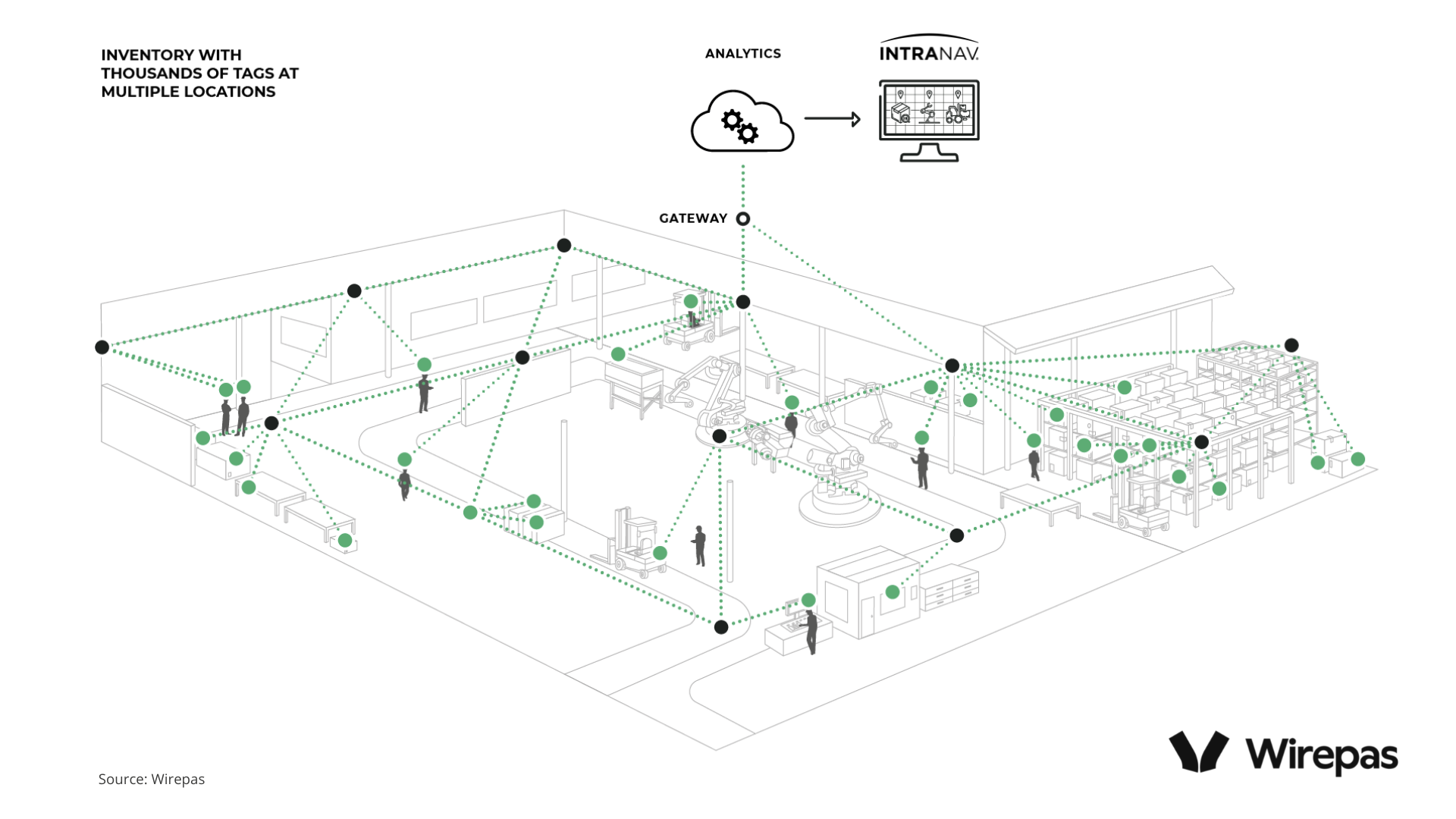

Dank des Multi-Technology Hubs von INTRANAV, ist eine sehr kosteneffektive Schlüsselfertige Lösung möglich. INTRANAV fungiert hier als integrative unabhängige Plattform und arbeitet mit RTLS TAGs von ELA Innovations, welche in diesem Use Case mit der neuesten Wirepas Mesh Technologie ausgestattet sind. Die Infrastruktur für diese Ortung ist batteriebetrieben und ist für eine Lebensdauer von bis zu 7 Jahren ausgelegt.

Ergebnis

Die integrative unabhängige INTRANAV.IO RTLS Plattform ermöglicht die Echtzeit Bestandsverwaltung aller Prototyp-Modelle, einschließlich Abrufbarkeit der jeweiligen internen Kennung eines jeden einzelnen Modells, hinter der sich weitere Informationen über Beschaffenheit, Art und Besonderheit des Modells befinden. Zudem ortet INTRANAV die Prototypen und ermöglicht zudem die Echtzeit-Zuordnung der Modelle in den verschiedenen möglichen Standorten.

Im Produktivsystem können Mitarbeiter nun nach Modellen zu suchen und erhalten den Echtzeit-Standort auf einem Grundrissplan als Digital Twin über ein beliebiges Device via INTRANAV.IO angezeigt. Hierdurch werden Suchzeiten vermieden und eine schnelle Auffindbarkeit ist garantiert. Mit INTRANAV können durch einfachste Prozesse neue Design-Modelle erfasst werden oder neue Standorte im System ergänzt werden. Das IoT Projekt beläuft sich auf ca. 4-6 Wochen für die komplette Umsetzung einschließlich Implementation. Dank Plug & Play Lösung wurde die Software innerhalb von einem Tag installiert und eingerichtet.

INTRANAV Benefits für kosteneffektives Equipment- & Inventar-Management

- Einfaches und standortübergreifendes Inventar-Handling, ermöglicht sofortige Übersicht (Digital Twin) wo sich das Inventar tatsächlich befindet, dank Echtzeitlokalisierung (RTLS)

- Echtzeit-Übersicht & Suchfunktion des gesamten Prototyp-Inventars

- Eintragen von zusätzlichen Informationen (Meta-Daten & Flags) und Dateianhängen pro Inventar-Objekt

- Inventarhistorie, wie hat es sich bewegt, wer hat es entnommen wie sind die Standzeiten und Lagerstandortkapazitäten

- INTRANAV.IO bietet eine moderne und ansprechende Nutzeroberfläche die auf dem Desktop Bildschirm als auch auf dem Smartphone optimal funktioniert.

- Das RTLS ist sehr kosteneffektiv und benötigt keine Verkabelung.

- Schnelle Umsetzung & Integration der schlüsselfertigen RTLS Lösung, ca. 4-6 Wochen

- Wireless RTLS Hardware mit hoher Batterielaufzeit bis zu 10 Jahren

- Die Batteriebetriebene Lösung garantiert eine Real-Time Location Tracking Genauigkeit von 3 bis 5 Metern.

INTRANAV bietet eine hochflexible und kosteneffektive Enterprise Lösung, ideal für Automotive, Aerospace oder Healthcare. Weitere Anwendungsfelder sind beispielsweise in Krankenhäusern, Medical Supply und Medical Equipment möglich. Unsere INTRANAV Warehouse Solution ist auch für Sie interessant, kontaktieren Sie uns, um bereits heute über Optimierungsmöglichkeiten Ihrer Warehouse und Logistik-Workflows zu sprechen!