04.08.2021

TB International controls and optimizes its intralogistics processes by digitizing its forklift fleet with INTRANAV

The successful wholesaler TB International GmbH, with up to 15 textile and accessories brands selling its streetwear to more than 15,000 retailers worldwide, ensures its long-term competitive advantage by applying the latest INTRANAV Virtual Warehouse solution.

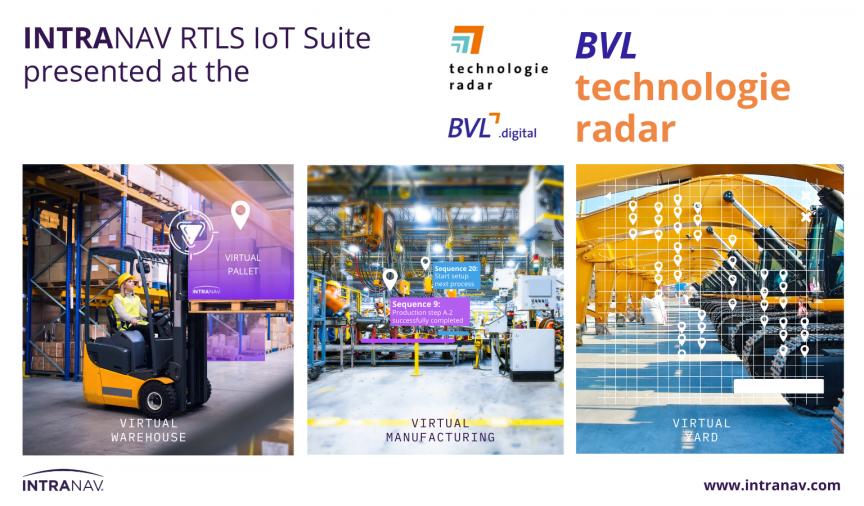

From goods receipt to shipping, TB Int. tracks and controls its intralogistics processes with the digitized forklift fleet powered by INTRANAV.RTLS VehicleTAGs+, based on a multi-RTLS layer with UWB and RFID technology. RFID sensors on the forklift enable the transport of pallets without scanning through all logistics zones on the shopfloor, including storage and retrieval to the RFID shelves. This eliminates manual steps, such as barcode scanning, and replaces them with AutoID – all done by the forklift!

Automatic order pool processing is controlled by a central system – the INTRANAV “Transport Pool”. This ensures process reliability, time-efficient transport orders, and vehicle orchestration. With the forklift cockpit “Transport Driver”, INTRANAV facilitates and accelerates order processing by indicating available transport jobs nearby the drivers.

Furthermore, the INTRANAV.IO platform APPs support employees with indications on how to load single-sorted pallets in order to avoid incorrect bookings and packing errors. Also, using events based on current location information and product identification, TB Int. ensures intelligent control of its processes, e.g. automatic initiation of transport orders by linking to SAP, creation of delivery slips, or the initiation of pick-up orders.

👉 Learn how TB Int. optimizes its material flow and logistics processes in one of our next case studies!

▶️ Learn more about our INTRANAV VIRTUAL Warehouse solution!