29.04.2021

Virtual process workflows and real-time analytics reduce process cycle times through resource-optimized yard management

At three locations of an internationally active compact and construction equipment manufacturer group, construction equipment ready for shipment is stored for pickup in the respective yards with areas ranging from 5,000 to 55,000 m²; the outdoor area is also used as a buffer area for the interim storage of unfinished products for production. Finished and unfinished products are widely scattered throughout the yards and parked according to space availability. In this process, the search process for the right resource can quickly become a “search for a needle in a haystack.” In addition, excavators pass through multiple stations in the yard, regularly resulting in high search efforts and costly waiting times. Congestion and unplanned stops accumulate due to blocked entrances and exits, inhibiting overall productivity in the production and handling process. In addition, it is not uncommon for unfinished components to be lost in the yard or forgotten in the production flow, again causing unnecessary replenishment needs and time delays in the production flow, resulting in delayed completion and on-time delivery. Thus, waiting product resources in the buffer zone remain partially unused and wastage occurs due to incorrect storage in the yard. As a chain reaction, the transport flow is unnecessarily increased and is therefore highly inefficient, as well as time and cost intensive.

Empty runs and long throughput times increase the unbalanced relationship between service level and costs incurred, the use of resources is therefore very high and the transport performance low. But also the personnel gets into dangerous situations by searching for components and vehicles from passing traffic. For the yard logisticians it is a big challenge to keep track of all resources, their status and movements. Until now, process corrections could only be made slowly and through inaccurate estimates; there was simply a lack of virtualization of material tracking and synchronization of logistics processes (warehouse and yard) with ongoing production.

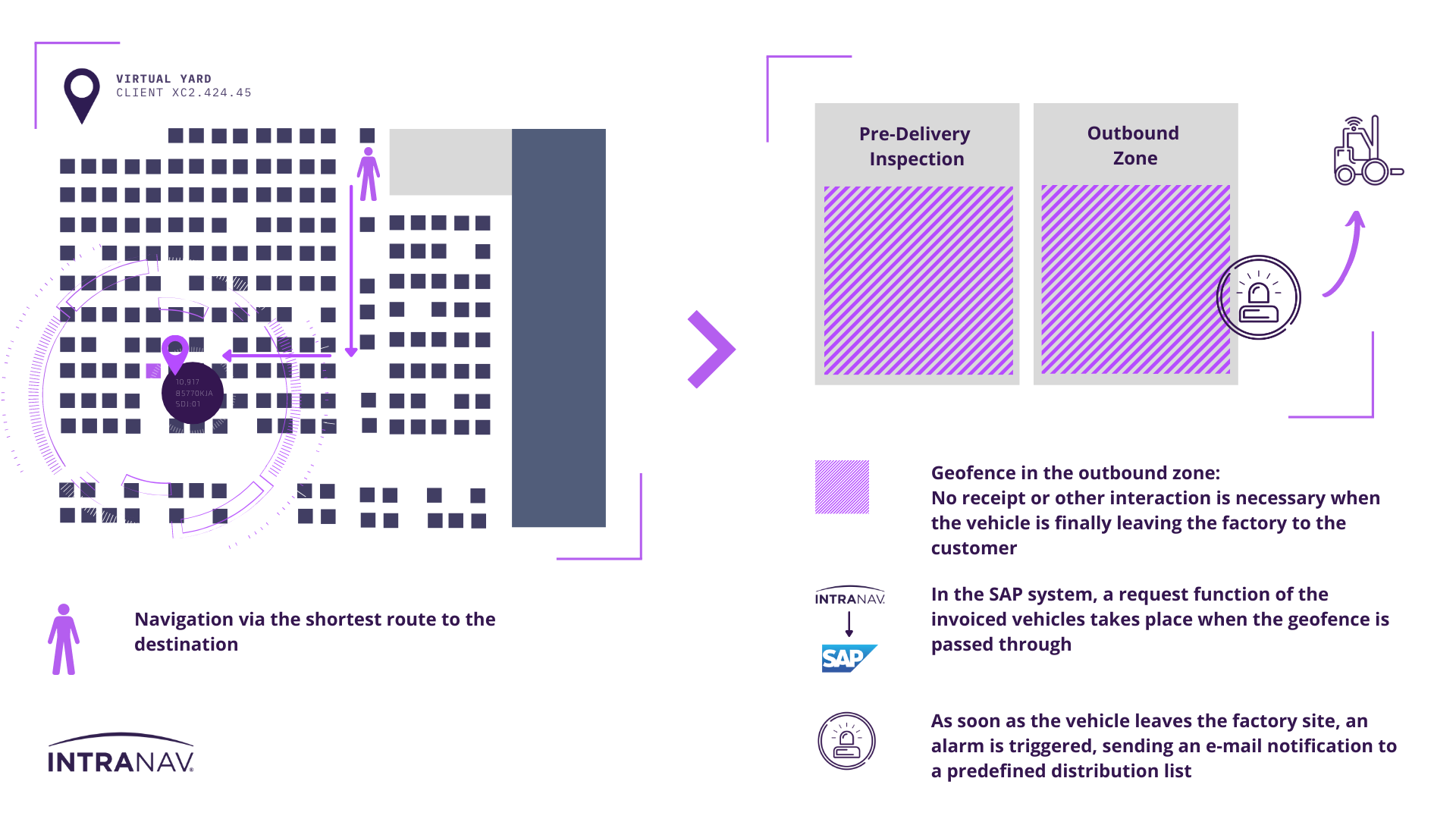

In the outbound process, there were also high search times in the yard because the buffer area of the finished products changes regularly. Accordingly, an RTLS solution with navigation function is needed for fast and timely dispatch. The entire handling process from pre-delivery inspection to shipment to the customer, should be optimized and simplified by automatic, real-time driven outbound processes, such as issuing invoices via SAP, scannerless status recording for shipment, customer and plant notification as soon as the product leaves the plant.

Since the production of one of the plants has already been digitized by INTRANAV and the control of the variant production has been automated by real-time data-driven process solutions, the extension of the Digital Twin to the yards was the next step to be able to guarantee an efficient organization of all logistic processes for the production and the outbound process. In addition, our customer was looking for a solution that would allow existing telematics systems, which are already integrated in the construction machines, but also additional outdoor TAGs, to be connected to an RTLS platform as a hybrid RTLS solution.

For a leading international manufacturer

of compact and construction machinery

The Group is a leading global manufacturer of high-quality light and compact equipment. Its range of products and services is aimed at professional users in the construction industry, gardening and landscaping, agriculture, as well as municipalities and industrial companies in sectors such as recycling.

Requirements of our customer

-

1

Real-time tracking and positioning of finished and unfinished products on the yard site

Streamlining through the virtualization of processes with the tracking of excavators, load carriers, industrial trucks and tools in the outdoor area

-

2

Yard navigation and scannerless outbound/shipping processing

Yard-Navigation über den kürzesten Weg zum Produkt sowie scannerlose Ausgangsabfertigung in der Outbound Zone, hierbei ist keine Quittierung oder sonstige Interaktion notwendig. Sobald das Fahrzeug das Werksgelände verlässt, wird ein Alarm ausgelöst, der eine Email-Benachrichtigung an einen vordefinierten Verteiler (bspw. Kunden) sendet.

-

3

System association of the TAGs with the FAUF (INTRANAV & SAP)

Associaton of the FAUF with the TAG label or telematics module, for safe, continuous order tracking in the yard.

-

4

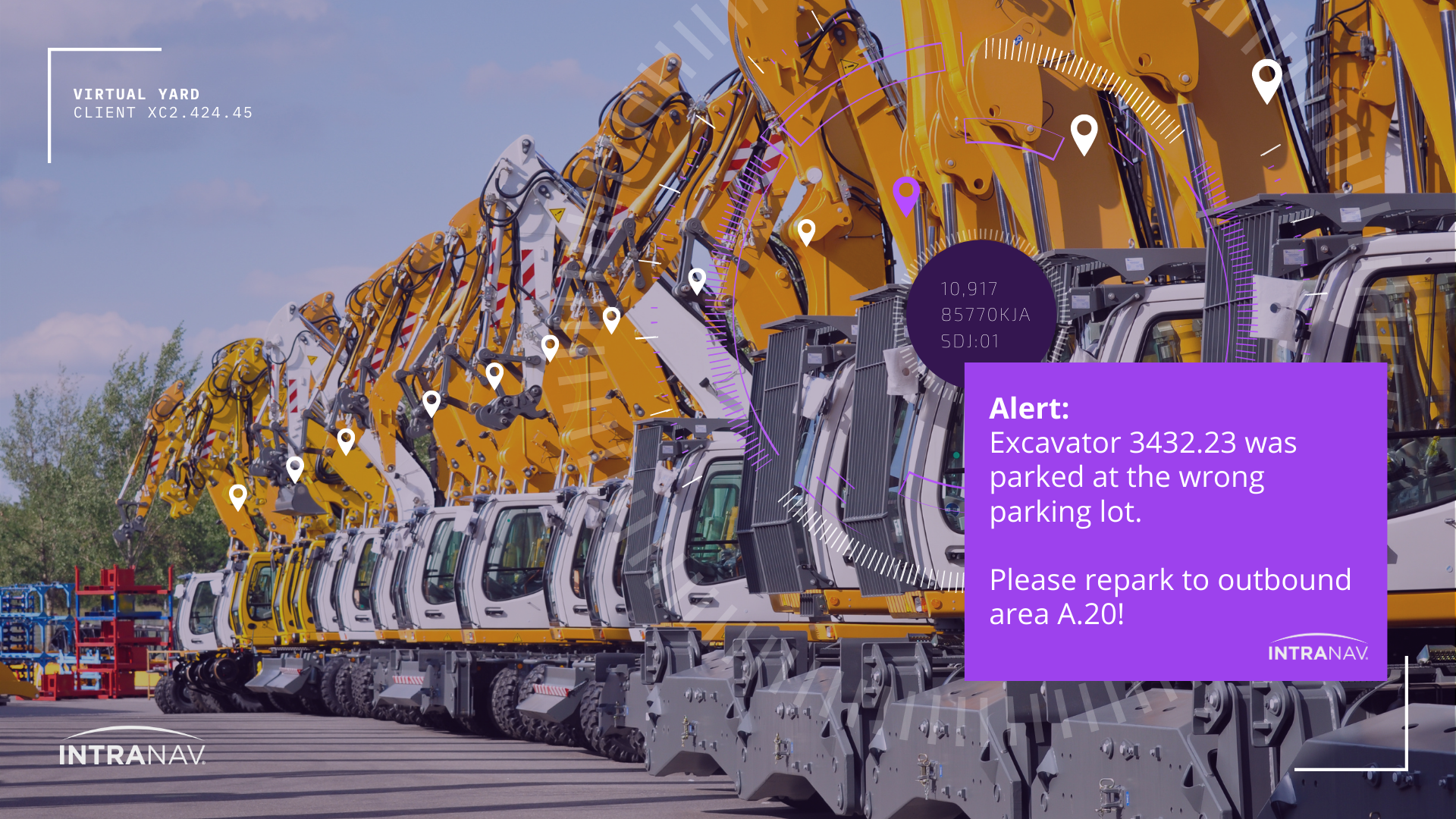

Alerts and process prioritization

Real-time location overview and search function of all construction machines, load carriers and persons located in the yard, including alerts to notify personnel in order to be able to react to undesirable situations in good time or to indicate misplaced, obsolete or out-of-zone storage.

With the connection to enterprise resource planning and production planning systems, processing and search processes can be automatically prioritized based on attributes.

-

5

Analysis and optimization of idle and throughput times

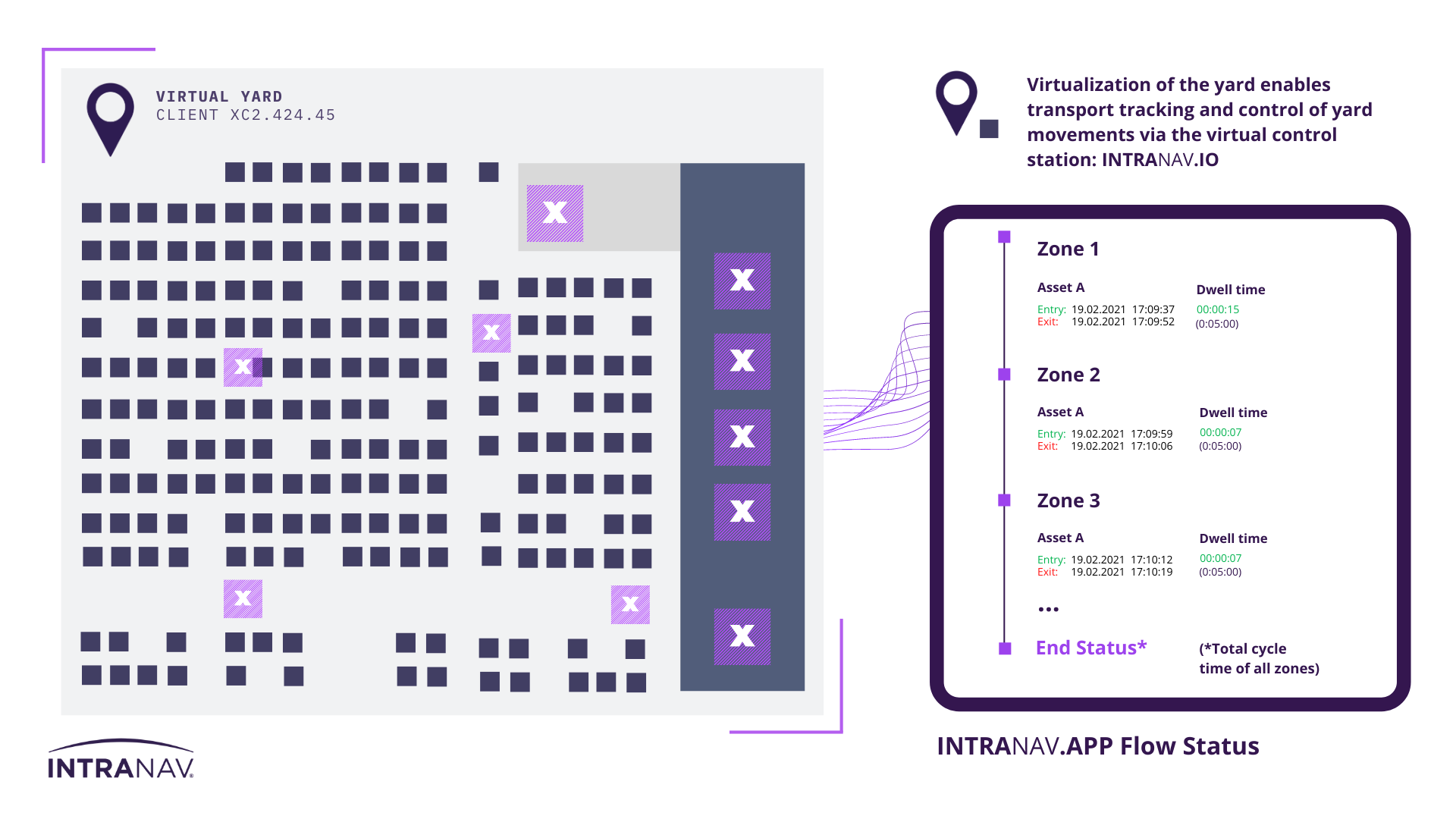

Increase planning certainty by analyzing bottlenecks with KPI reconciliation such as dwell times, cycle time, stops, malfunctions, delays, process length, or total time required for a complete cycle

-

6

Safety Management & Collision Avoidance

Loading and transport traffic in the immediate vicinity of the vehicles and persons is detected and hazardous situations are avoided by acoustic warnings and display indication

Solution from INTRANAV

To enable the construction equipment manufacturer’s main goal of reducing search and wait times, as well as virtualizing the entire yard, we implemented our INTRANAV Yard Management Solution. This includes equipping excavators and finished products with our INTRANAV.RTLS AssetTAG+, which is designed for high-performance supply chain tracking and seamless transition from indoor to outdoor tracking. Thanks to its multi-modal tracking technology based on GPS, Bluetooth, and WiFi, it enables global supply chain tracking, integrated sensors reliably monitor the condition of excavators and semi-finished products. INTRANAV.IO virtualizes and manages yards with real-time vehicle location data as a real-time digital twin. The integrated telematics modules are connected to the INTRANAV.IO system via the open API, enabling INTRANAV to provide a hybrid real-time tracking solution and again saving our customer costs in equipping additional hardware.

A complete digital capture of the flow of goods and values in the yard area and the potential of real-time optimization of processes is increased so that the cost savings and quality improvements can actually be measured in an order of magnitude. In particular, the real-time inventory overview and the search function increase the availability of semi-finished and finished products. Thanks to the virtual mapping of yards, assets can be found again immediately and without any risk of confusion, while at the same time capacity planning is possible at a glance.

For the real-time status tracking of the finished excavators in the yard with the many different product groups, the TAGs, or the own telematics module via inital scan, must be associated/married once with the QR code of the FAUF in the INTRANAV.IO platform and SAP. First the vehicle is scanned, INTRANAV recognizes via interface call whether it is a telematics module or whether the INTRANAV.AssetTAG+ is necessary, this is output to the personnel via a corresponding dialog box. The TAG is attached with a self-releasing cable tie. INTRANAV automatically triggers the marriage process in the system by driving the TAG into a geofence. Subsequently, a call of the real-time position and associated documents can be made via any device using the INTRANAV.IO platform.

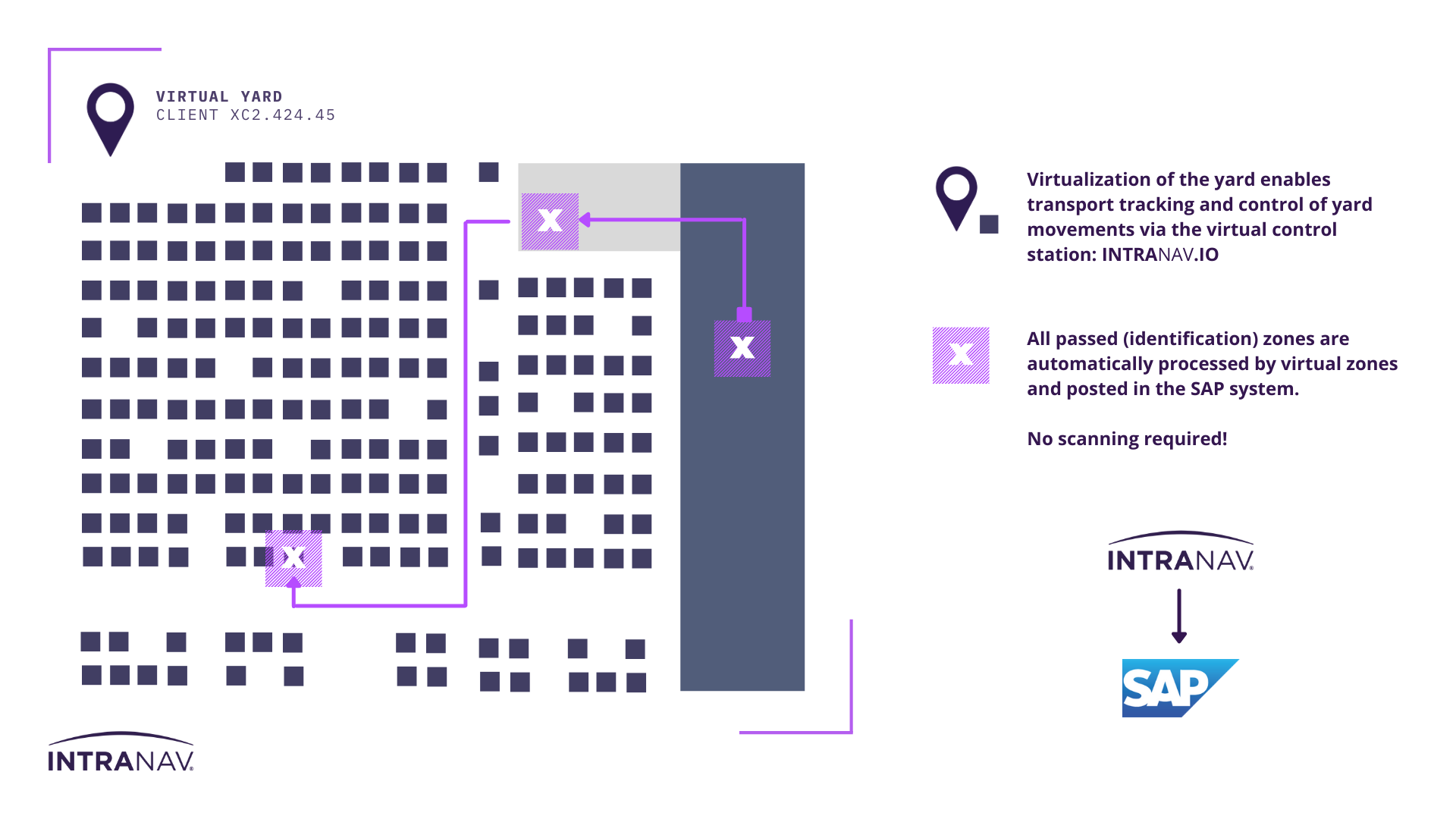

INTRANAV’s IoT sensor-based RTLS solution tracks objects from their starting point to their destination point and across all intervening nodes (warehouse levels/buffers) in real-time. In the process, all objects to be tracked are automatically recorded in the SAP system at all nodes through geofencing and auto-identification, which optimizes the entire material and transport flow.

Warning messages immediately identify incorrect storage in the yard and automatically alert the relevant employee, thus preventing the accidental misplacement of resources. To ensure that wasted materials and “forgotten” storage capacities no longer block the plant yard but are used when they are actually needed in production, an alert is also issued here if the specified storage time is exceeded. This allows space and plant resources in the yards to be used efficiently and reduces capital and operating costs. Resource aging, damage or loss is proactively avoided with INTRANAV.

Intelligent process prioritization with data reconciliation of the ERP and PP systems enables work-in-process and associated transportation tasks to be prioritized according to delivery dates and production time limits. Variables such as status, delivery plans and schedules are taken into account to achieve production targets and improve lead times.

Personnel are notified of process-critical situations, such as delays, via warning messages, which increases resource utilization in production, logistics and yard and thus improves on-time delivery. Dangerous situations such as collisions or entering danger zones are avoided by means of acoustic warnings and display messages for drivers or personnel on foot, which significantly increases safety in the yard.

Our client can seamlessly track its finished goods across halls from indoor to outdoor in real time to determine the exact location when searching. Thus, transport chains can be traced back in real time and retrogradely by material flow analyses, which enables overarching process optimizations (yard – factory) such as the reduction of empty and throughput times. Bottlenecks are revealed by means of a software-based KPI comparison, dwell times, throughput time, stops, malfunctions, delays, process length or the total time required for a complete cycle. The resulting increased productivity in the yard ensures reliable production supply and optimized material flow.

For goods tracking, analysis, and the notification system, INTRANAV.IO offers an intuitive user interface for appropriate user management. The real-time digital twin ensures efficient fleet utilization and sustainably improves the value stream and the supply chain, making the construction equipment manufacturer optimally prepared for future logistical challenges.

A virtual list of deliveries for the next day is provided for seamless product shipment to the end customer. Personnel enter the equipment serial number (ID) or FAUF number into the INTRANAV Inventory Search application. Immediately, the real-time location of the vehicle in the yard is displayed to the personnel. To navigate the shortest route to the destination, personnel are shown their own location as a reference point and the route relation to the vehicle on the outdoor map. Once the person has arrived at the vehicle, a final identification of the searched object takes place via a comparison of the Excel list with the product nameplate. The product is then driven to the pre-delivery inspection for a final check, where it is inspected and cleared for shipment. The outbound zone is geofenced, which means that no acknowledgement or other interaction is required when the vehicle leaves.

A query function of the invoiced vehicles now takes place in the SAP system. As soon as the vehicle leaves the factory premises, an alarm is triggered, whereby an e-mail notification is sent to a predefined distribution list. Via this interface the customer is informed about the shipment of his ordered unit.

The return of the INTRANAV.AssetTAG is done via the physical end moon tag in the exit zone. The INTRANAV.APP recognizes if it is a vehicle with an INTRANAV TAG and a demounting is necessary. The TAGs are then stored in a collection bin, once per day the bin is returned to production. If the TAG is remarried, it is overwritten at the same time.

Solution

With the virtualization and scannerless recording of all nodes in the yards, the construction equipment manufacturer is able to reduce its search efforts, so that the entire material and production flow is significantly improved by the punctual delivery from the yard. By tracking the individual assets, the personnel can head for the finished and semi-finished products in the buffer zones on a direct route and manually navigate to the destination, thus avoiding detours and long walking distances in the yard, and the working time can now be used for value-adding activities. Process prioritization enables time-efficient work and transport handling, alerts avoid incorrect resource allocation, as well as material wastage due to “forgotten” products. Analyses help to uncover bottlenecks and critical, time-delaying processes through systemic KPI reconciliations and reduce lead times in yards and production. The outbound process is simplified and made more secure by automation steps, write-offs are completely scanner-less, seamless invoice issuance is triggered, customers and staff are informed via alerts that the vehicle is leaving the plant.

Summary of the results achieved by our customer with INTRANAV:

● Virtualization of the yard enables visual transport tracking and manual control of yard movements via a graphical control station

● Complete process transparency in material flow.

● Inventory management enables efficient fleet utilization

● Cost savings and quality improvements through efficient resource utilization

● Higher productivity through process automation and reduction of manual steps (AutoID)

● Reduction of working and dwell times

● Reduction of walking distances by navigation to the destination

● Time savings due to the reduction of search efforts

● Reduced process cycle time through time-efficient material management

● Minimized empty runs

● Identification of bottlenecks

● Efficient fleet utilization

● Reduced control and posting effort; Optimized shipping processing through customer interface

● Improved adherence to delivery dates

● Reduced lead times by recording and evaluating all individual nodes

● KPI-based reports for maximizing transport performance and utilization

● Archiving and historization of fleet movements.

● Cross-location networking of yard processes enables rapid responsiveness within the supply chain and overarching optimization potential

● Control of third-party systems (traffic lights, terminals, smartphones or gates) ensure efficient yard processing

INTRANAV Benefits through the virtualization of the yards and processes

- Real-time tracking and positioning of finished and unfinished products on the yard site.

Streamlining through the virtualization of processes with the tracking of excavators, load carriers, industrial trucks, and tools in the outdoor area - Automatic recording of nodes in the SAP system

Process automation in the yard eliminates individual identification and booking steps - Yard navigation and scannerless outbound/shipping processing.

Navigation to the vehicle, as well as automatic booking of the last process steps in the plant (status booking, issuing of the invoice, information to customers as soon as the product leaves the plant) - Coupling of the FAUF with the TAG label or telematics module Enables safe, continuous order tracking in the yard

- Process prioritization

With the connection to enterprise resource planning and production planning systems, machining and search processes can be automatically prioritized based on attributes - Inventory management: Alerts and search function

Real-time location overview and search function of all construction machines, load carriers and persons located in the yard, including alerts to notify personnel in order to be able to react to undesirable situations in good time or to indicate misplaced, obsolete or out-of-zone storage - Monitoring of cross-hall transports

Transport chains are seamlessly traceable between indoor and outdoor areas - Analysis and optimization of idle and throughput times

Increase planning reliability by analyzing bottlenecks with KPI comparison such as dwell times, throughput time, stops, malfunctions, delays, process length or the total time required for a complete cycle - Monitoring of assets and associated FAUF in the buffer zone

Control and monitoring of resources and transfer orders with the associated production orders - Safety management & collision avoidance

Loading and transport traffic in the immediate vicinity of the vehicles and persons is detected and hazardous situations are avoided by acoustic warnings and display indication - Condition monitoring and KPI reconciliation

Monitoring of transport direction values, such as temperature, humidity, and acceleration - Integration of further positioning technologies

Possibility of integrating further positioning technology (e.g. RFID, BLE, WiFi) into the respective software solutions. - Interfaces to ERP and subsystems

Industry-standard APIs enable easy and efficient integration into the existing IT landscape and third-party systems. INTRANAV.IO can be connected bi-directionally via an SAP interface to transmit transport orders and their feedback.

INTRANAV offers a highly flexible and cost-effective enterprise solution, ideal for automotive, aerospace, logistics or production. Further fields of application are for example in the area of production line automation; automatic cycle feedback into SAP systems, line balancing / production leveling by INTRANAV SMART Warehouse Solutions, “Just in Sequence” – provision for the right sequence, plausibility checks, or zone-based control of automatic programmable logic controllers.

Our INTRANAV Production Solution is also interesting for you, contact us to talk about optimization possibilities for your production and logistics workflows already today!