27.07.2021

Virtual production monitoring and control with real-time location

and E-Ink displays

Our client’s powder production includes several processing methods and process steps. The powder containers pass through multiple stations and underlie various quality tests. Therefore, tightly timed status updates, recording, and booking of the various containers and processes are necessary throughout the entire production process. The time-consuming, paper-based manual process monitoring consumes a large part of the employees’ working time and is also error-prone. The production process extends over several zones and buildings, and the individual stations could only be monitored by manual recording. If a container is ready for pickup or if a process step deviates from the production specifications, this may only be noticed by a delay. Production zones are also subject to certain safety regulations, which is why entry or further processing may only be carried out by authorized personnel.

The goal of the company is the digitization of the individual production steps as well as the most efficient utilization of resources while maintaining quality and safety standards. In line with INTRANAV Virtual Manufacturing Solutions, we implemented an RTLS solution that included real-time location, automated workflows interacting with electronic displays, and analysis options.

For a global leader for affordable

and sustainable energy

The energy company is one of the leading international providers of sustainable, reliable and affordable energy products, solutions and services along the entire energy value chain. In more than 90 countries and with 90,000 employees worldwide, the company supports its customers on their way to a sustainable future.

Process requirements of our customer

-

1

Location and batch tracking of powder containers

Centimeter-precise site localization and process tracking through ultra-wideband-based INTRANAV.RTLS TAGs, enable digital mapping of the powder manufacturing process.

-

2

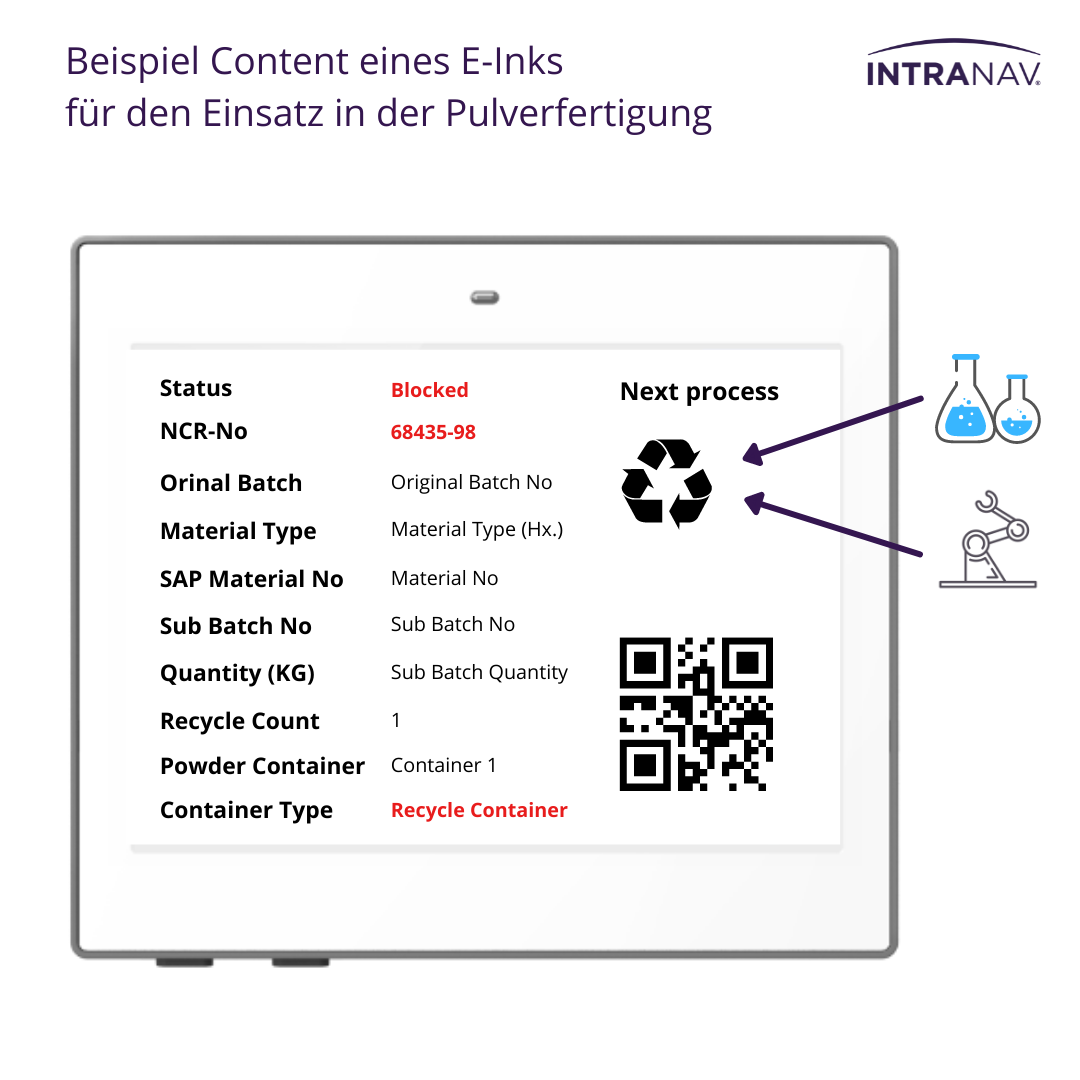

Paperless factory: real-time status updates through E-Ink TAGs

Real-time status updates via E-Ink TAGs: Status, material number, batch number, batch barcode, quantity, SAP material number, number of reuses, powder container, container type.

-

3

Alert notifications in case of process deviations

Real-time location and status updates enable platform-based notifications as soon as predefined processes deviate from target values.

-

4

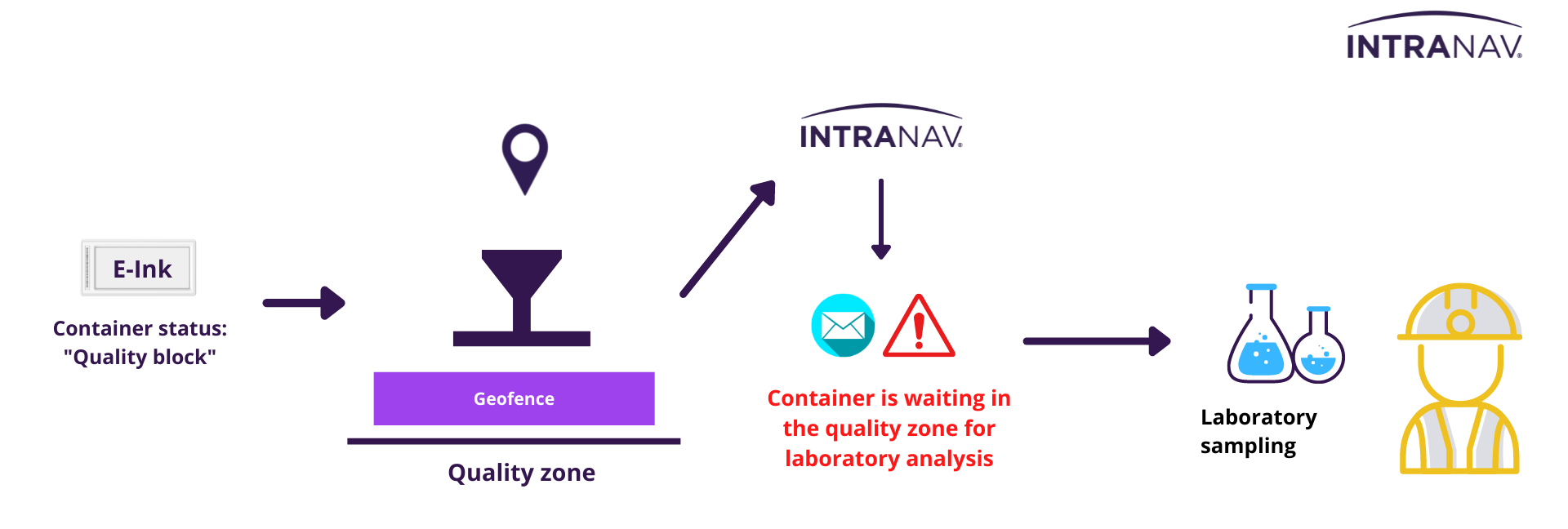

Initiation of follow-up processes through geofence-based workflows

Event triggers initiate e.g. process blocking, process release or notification for internal transport.

-

5

Workflow optimization through process and material flow analyses

INTRALYTICS provides analytics of all movement and location data to be able to optimize workflows between processes. Such as: Dwell times, idle times, throughput times, trails as structured data export via CSV.

-

6

Quality locking and authorization

Through the interface to the SAP MES, location-based information can be used to lock or unlock processes.

IoT Requirements for INTRANAV

-

Data transfer and interaction from cloud to local edge

-

Interaction between RTLS TAG and the E-Ink display

-

Interface to the Mendix App and SAP

INTRANAV Real-Time Digital Twin:

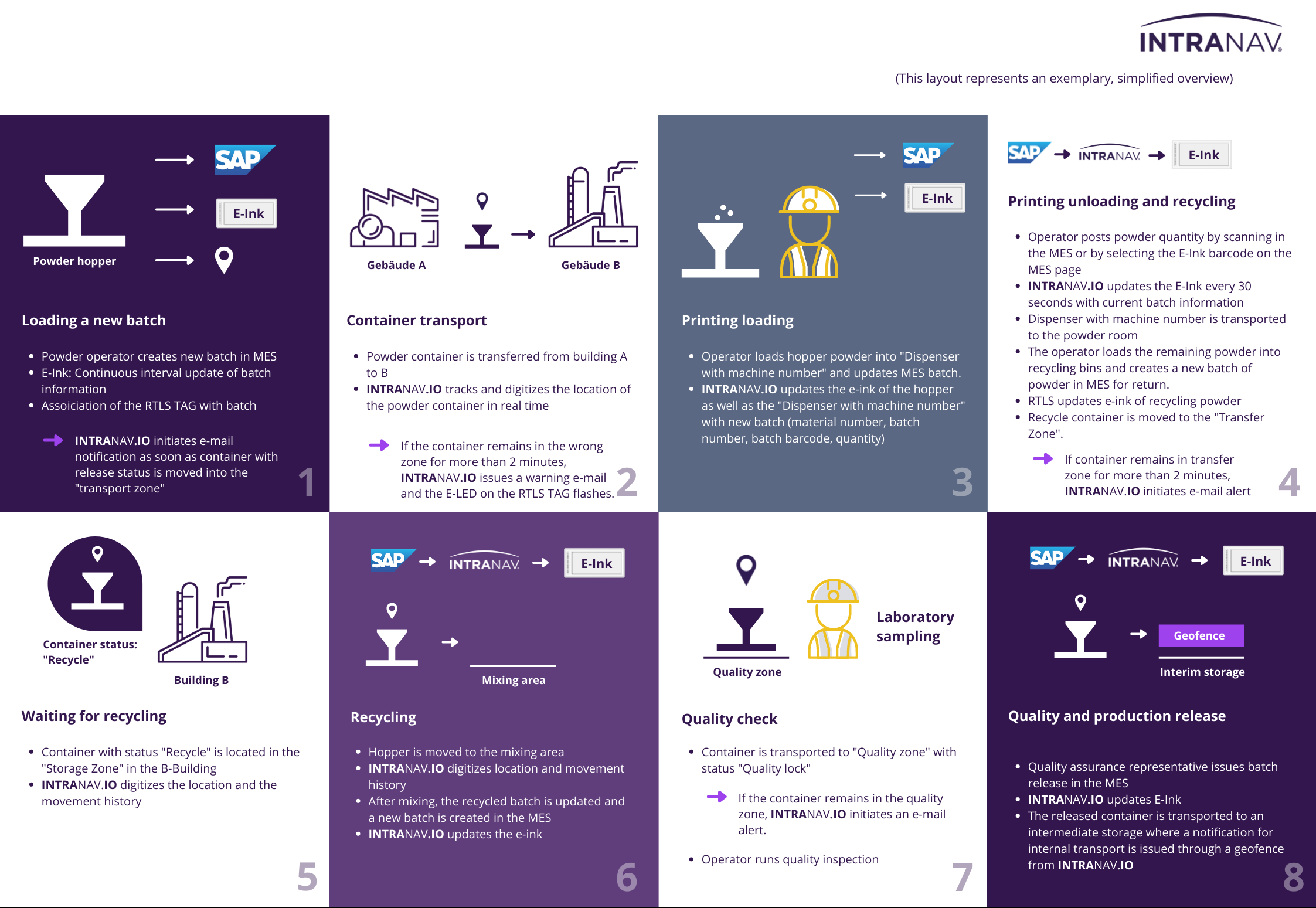

Mapping the powder manufacturing process

Solution from INTRANAV

The key for monitoring every step of the powder manufacturing process in real-time, reducing manual processes in production and moving to 100% paperless production is to use the INTRANAV IoT Edge Suite in collaboration with E-Ink Labels.

This is how the energy company uses INTRANAV in its

powder manufacturing process:

-

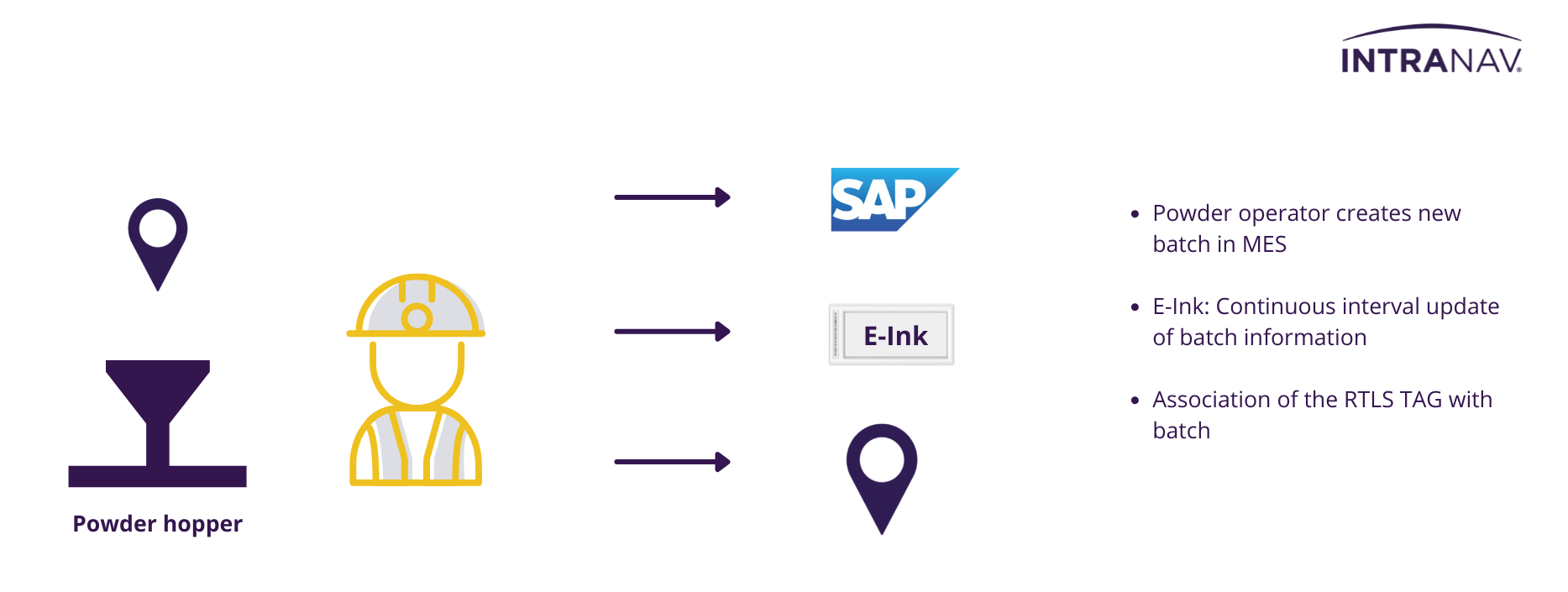

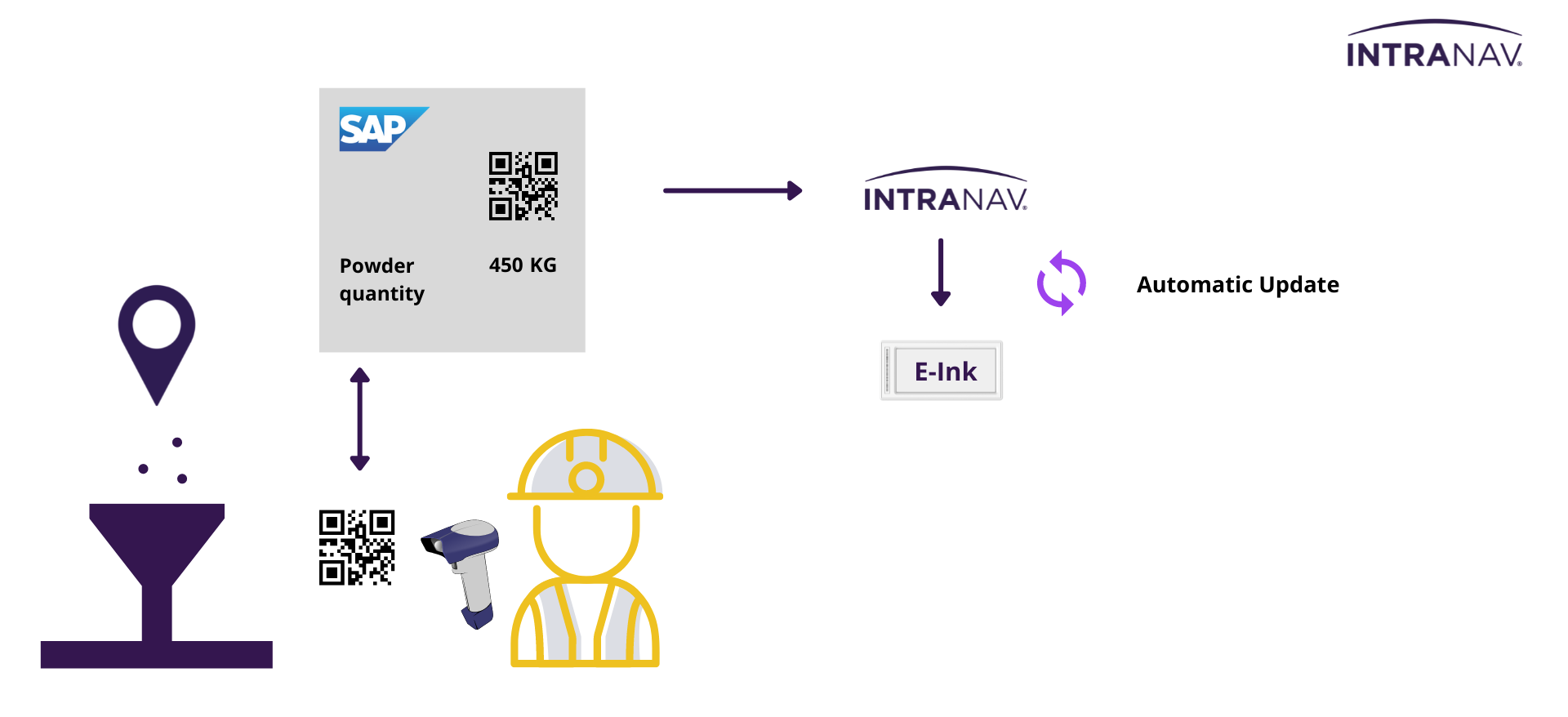

● Powder handler creates new batches in MES

● Within an interval of 30 seconds, the e-ink is updated with the new batch information (material number, batch number, batch barcode, quantity, batch status, container ID).

Alternative by a manual update: The powder plater hits the function key of the e-ink and thereby triggers the update of the e-ink content.

➜ Process assurance by INTRANAV: If RTLS could not find the correct container ID from the system for the batch number (due to incorrect entry), INTRANAV.IO issues an error alert to the administrator.

➜ Process assurance by INTRANAV: If RTLS could not find the correct container ID from the system for the batch number (due to incorrect entry), INTRANAV.IO issues an error alert to the administrator.

-

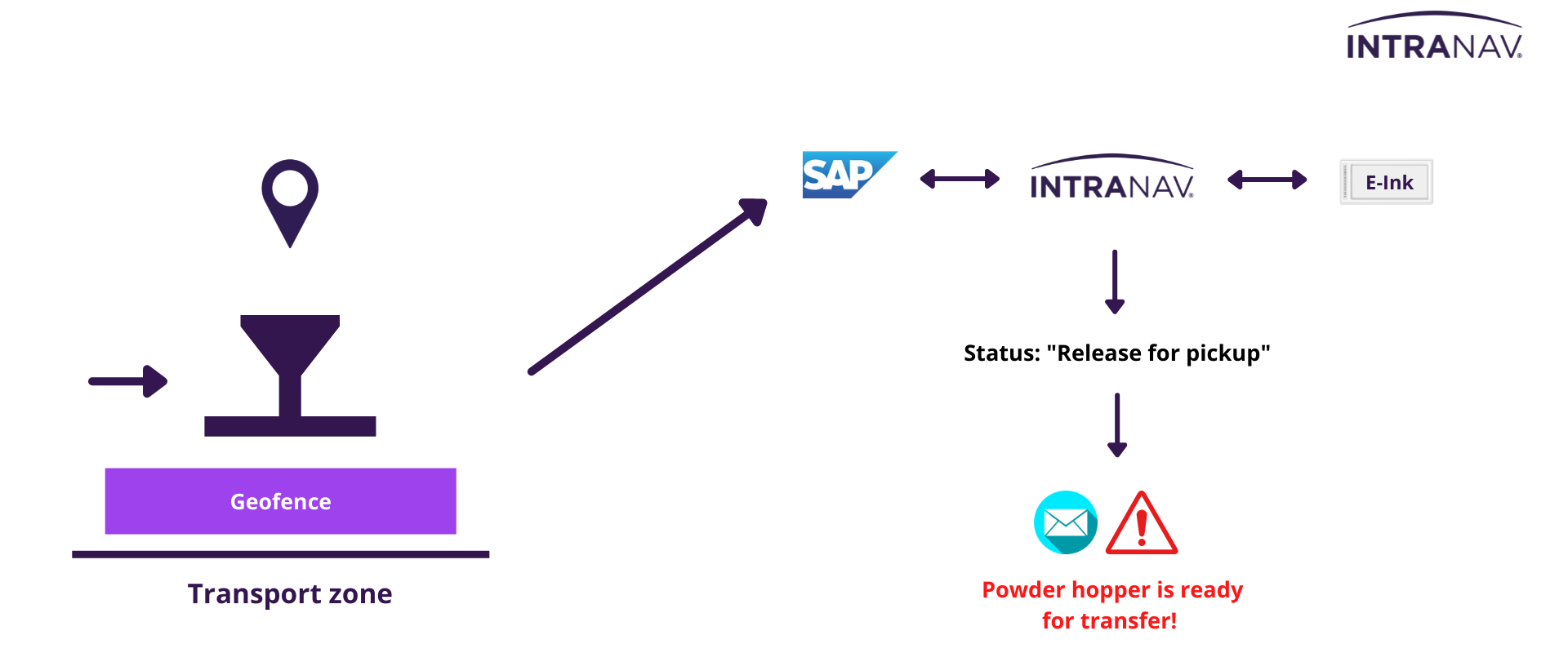

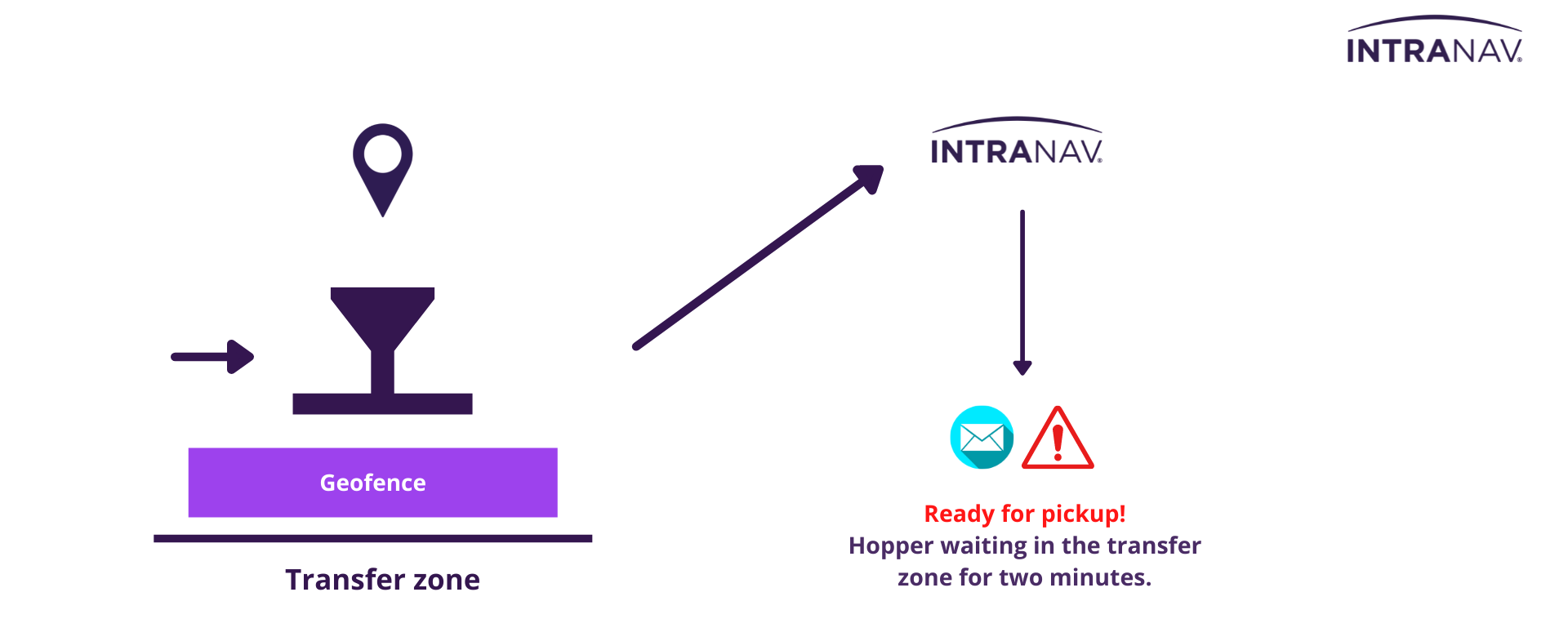

Transfer request

● If the container with the release status is moved to the “transport zone”, INTRANAV.IO initiates an e-mail notification.

● The operator could use the report to check the position of the containers in the map with different filters (status, material number, container ID, batch number).

➜ Process control by INTRANAV: If the container with incorrect status (status not authorized, quantity does not correspond to the pre-set kg) remains in the transport zone for 2 minutes, INTRANAV.IO initiates an alert e-mail notification, and the LED flashes red until the container is moved from the defined zones.

Transfer

● The operator physically transfers the released container from the transfer zone in building A to the designated area in building B.

● Location and movements are tracked by INTRANAV.IO.

➜ Process reliability by INTRANAV: If the hopper remains in the wrong zone for 2 minutes, INTRANAV.IO triggers an alert e-mail and a flashing of the E-LED.

-

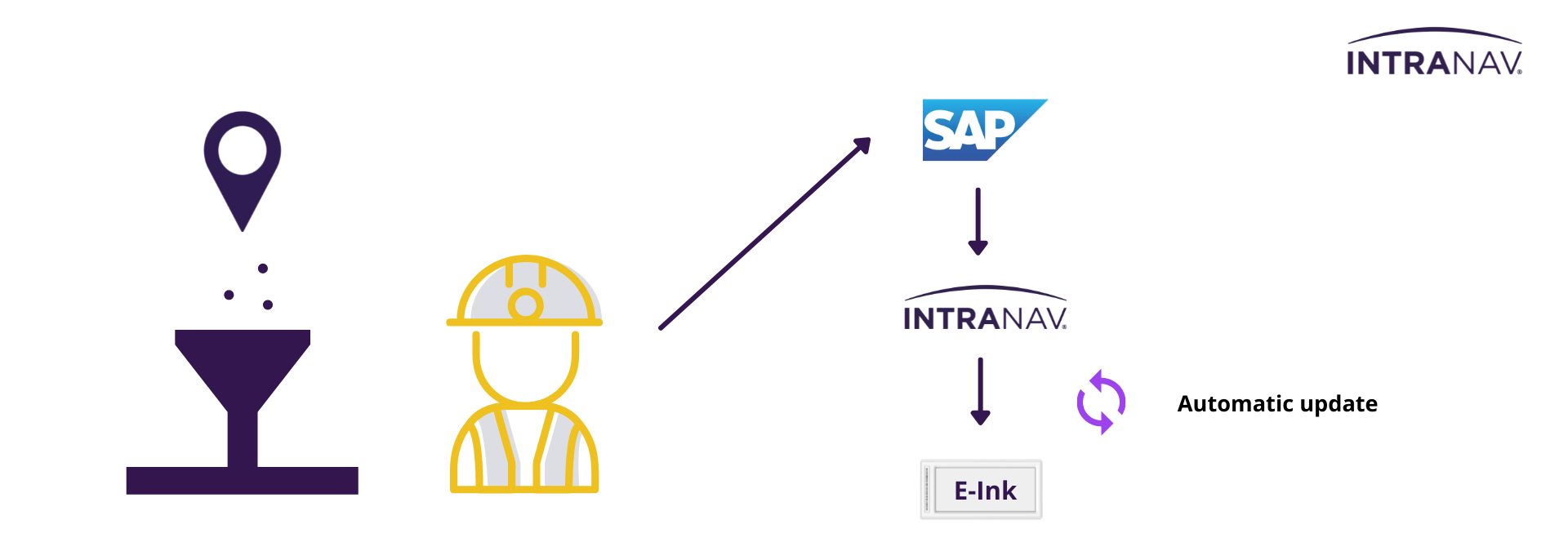

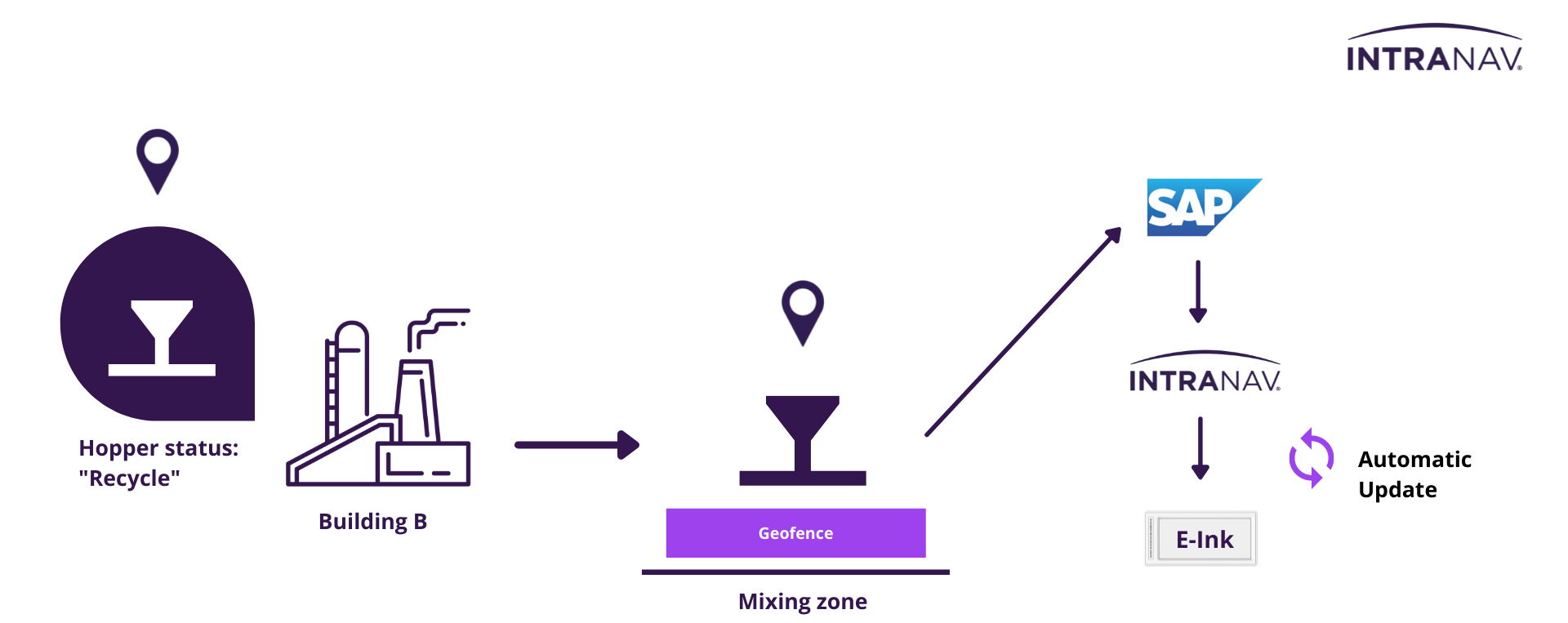

● The operator loads hopper powder into the dispenser with machine number and updates MES batch.

● INTRANAV.IO updates the hopper E-Ink and the dispenser with the new batch (material number, batch number, batch barcode, quantity).

Manual operation: The operator initiates the update of the e-ink by pushing the function key to update the e-ink.

-

When the print job is finished, the operator posts the corresponding powder quantity by scanning in the MES or manually selects the E-Ink barcode via the MES powder consumption page.

● INTRANAV.IO updates the batch information of the E-Ink every 30 seconds. Alternatively, this can be initiated manually via the function key on the e-ink.

● The dispenser is transported into the “Powder room”.

● The operator loads the remaining powder into the recycling container. The operator then creates a new batch of powder in the MES for recycling.

● INTRANAV.IO updates the e-ink of the recycling powder (with status “in use”).

➜ Process control by INTRANAV: When the production hopper is moved in the recycling zone, the RTLS initiates blinking of the E-Ink for alerts. Reverse for recycling hopper.

-

● The recycle bin is moved to the “Transfer Zone”.

➜ Process control by INTRANAV: INTRANAV.IO initiates an e-mail notification if the hopper remains in the “transfer zone” for 2 minutes.

-

● Container with status “Recycle” is located in the “Storage Zone” in B-Building, INTRANAV.IO tracks the location and movement history.

● Hoppers are moved to the mixing area, INTRANAV.IO tracks location and movement history.

● After mixing, the recycled batch is updated and a new batch is created to match it in the MES (new batches with the status “quality lock”).

● INTRANAV.IO updates the e-ink according to how it was defined in the previous steps.

-

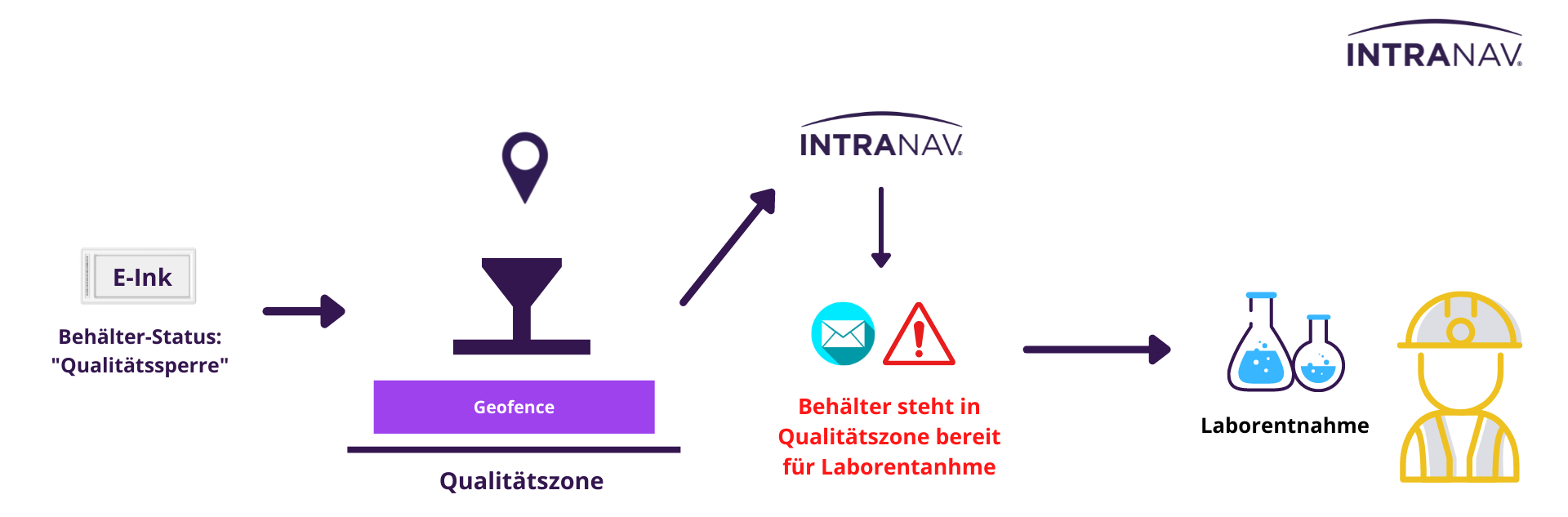

● Operator moves the container with status “Quality lock” to the “Quality zone”.

● When the container stops in the “quality zone”, INTRANAV.IO initiates an e-mail notification.

● Quality operator removes the sample from the hopper and carries out the powder test in the QMS.

-

● Quality manager releases the batch in the MES and INTRANAV.IO will refresh the e-ink accordingly.

● The “released” containers are moved to the interim storage, which initiates the notification for internal transport.

Results

Summary of the results achieved by our customer with INTRANAV:

● With real-time location tracking of powder containers via the Digital Twin RTLS platform, the energy company monitors the real-time status of all production steps. Downtimes, interruptions. Errors in the process flow can be identified immediately and eliminated more quickly.

● The interaction between RTLS and E-Ink Labels allows the transition to the digital factory (Paperless Factory), eliminating all manual data entry efforts and removing the need for manual updates. The batch/status updates of the E-Ink are performed automatically by the real-time location of the container.

● Real-time notifications of the current production status, such as “too long dwell time in one zone”, “container is ready for pickup” or “the container is located in the quality zone” ensure that the entire production process is performed on time and in quality.

● Real-time alerts, e.g. if the containers have been transferred to the wrong zone or an indication of a manually required interaction, enable fast intervention in case of process deviations in order to avoid long waiting times of the production flow.

● Automated workflows initiate further follow-up processes, such as blocking safety zones (so-called quality blocking or release) or initiate pickup orders.

● Material flow and resource utilization analyses by INTRALYTICS, the INTRANAV.APP “Flow Status” or the structured data export via CSV and the associated integration in analysis tools such as Power-BI, allow the determination of downtimes, idle and throughput times or zone occupancy periods as well as their utilization. For this purpose, INTRANAV records the exact time stamp (day / hour : minute : second) of the input and output of the respective zones and calculates, for example, the dwell time in the respective zone to the second. The final status indicates the total time of the transit of all zones and intermediate transit times per asset/package/material flow relationship. Based on the historical data of the completed transports as well as the dwell times of the containers at the passed zones, process optimizations of the production flow can be implemented.

INTRANAV.RTLS E-Ink TAGs

for paperless logistics & production.

E-Ink TAGs can drastically reduce logistics and manufacturing processes. In combination with our INTRANAV.IO platform, customers can now send location-based information and instructions to the E-Ink display to automate and optimize processes on the shop floor or in the warehouse. Create workflows, rules and generate content depending on real-time information. (The E-Ink TAGs are an INTRANAV.RTLS partner product).

Our INTRANAV software suite offers a broad portfolio of

pre-built E-Ink applications:

- Dynamic information for inventory & asset flow control.

- Real-time assembly line & manufacturing management.

- Dynamic picking and item lists updated by events and order information.

- ERP / WMS / MES interfaces to visualize critical information as changes occur for maximum flexibility

- E-Kanban by using the integrated buttons

- Real-time track & trace with additional information and work instructions

- Pick-by-Light for faster picking in the warehouse and at the assembly line

- Machine information and order progress

True Values through the use of the INTRANAV SMART Production solution and E-Ink Labels.

-

- Benefit:100% process transparency through digitization and monitoring of the actual manufacturing process

- Benefit: Paperless handling eliminates manual data entry efforts. Freed-up working time, as a result, can be invested in value-adding work.

- Benefit: Increased process reliability through KPI monitoring, alerts and automatic process blocking and release.

- Benefit: Real-time process triggers reduce manual effort and ensure timely compliance with processes.

- Benefit: Reduction of search times

- Benefit: Minimization of process deviations

- Benefit:Optimization of resources and capacity utilization in the sense of lean production: reduction of downtimes, throughput times, detours and process waste. Efficient route planning, production capacity utilization, area utilization and optimization of the production layout.

INTRANAV offers a highly flexible and cost-effective enterprise solution, ideal for automotive, aerospace, logistics or production. Further fields of application are for example in the area of production line automation; automatic cycle feedback into SAP systems, line balancing / production leveling by INTRANAV SMART Warehouse Solutions, “Just in Sequence” – provision for the right sequence, plausibility checks or zone-based control of automatic programmable logic controllers.

Our INTRANAV Production Solution might also be of interest to you, contact us to talk about optimization possibilities for your production and logistics workflows today!