17.05.2021

INTRANAV VIRTUAL Manufacturing – Digital Twin controls industrial manufacturing complexity

The complexity of manufacturing is increasing rapidly. As production requirements become more demanding, higher quality standards are required, while the customer expects a constant or even shortened delivery time. The INTRANAV process virtualization platform is THE KEY to a high automation level of manual manufacturing processes through real-time indoor track & trace data and digitized workflows.

Our customer has already achieved control of variance in manufacturing, with INTRANAV. Manual scanning efforts have been eliminated and search times significantly reduced. With the real-time data-driven plausibility check, the manufacturer ensures quality assurance for the further assembly process in its plant.

You want to control your production line in real-time, eliminate material mismatches during assembly, avoid idle times, and increase cycle rates?

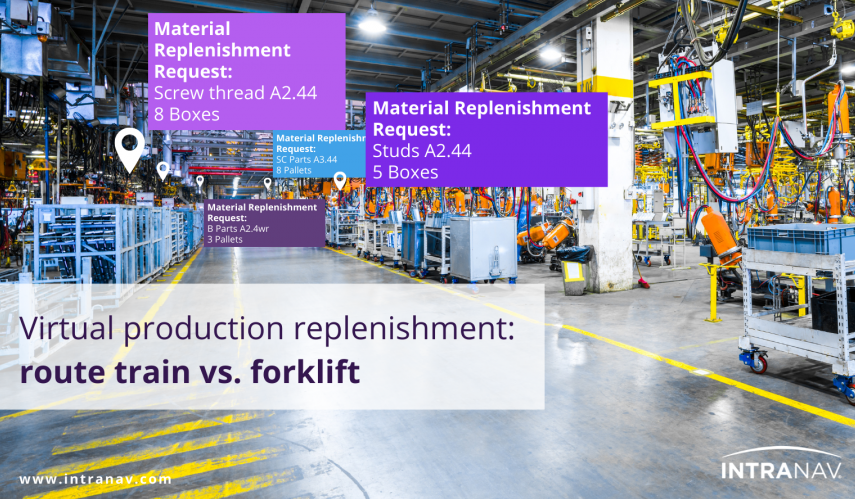

➜ Learn how to virtualize your production, use production controlling and dynamic production replenishment for an optimized manufacturing process, and finally establish synchronicity between pre-assembly and main assembly with our VIRTUAL Manufacturing Solution!