Integrated sensor data monitoring for compliance with storage and transport regulations

Get to know how you can use INTRANAV SMART sensors for reliable sensor data monitoring of your objects, freight and vehicles.

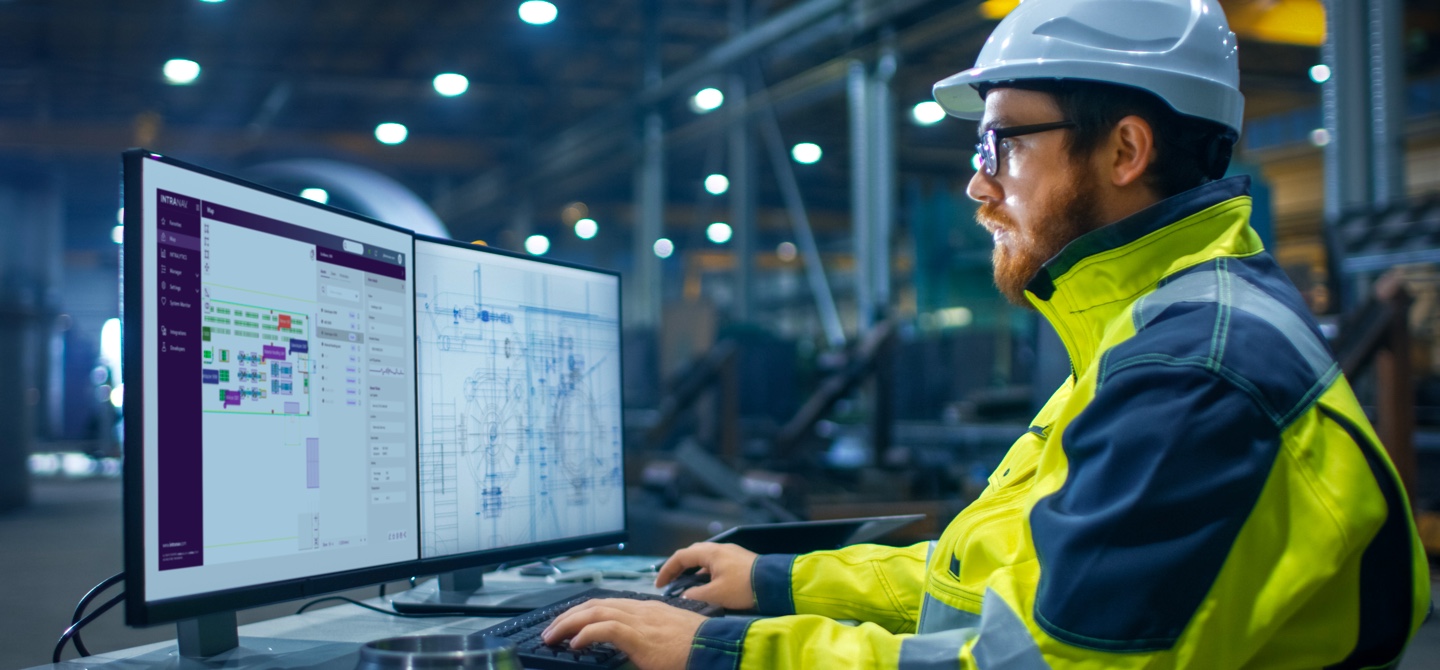

Sensor data monitoring

Indoor, yard & global management

-

Precise positioning of the forklift truck fleet on the shop floor (indoor) and in the yard (outdoor) through live display on the INTRANAV.IO map

-

Route and vehicle utilisation optimisation

-

Automated triggering of processes (e.g. door opening, warning lights, etc.)

-

Cargo monitoring by INTRANAV SMART sensors

-

Warnings in case of dangerous situations, process interruptions or if unauthorised zones are entered on the premises

Contact us

Cold chain monitoring

Indoor, yard & global management

-

Storage safety: compliance with the storage and transport guidelines

-

Transport safety: ensuring the transport guidelines, maintaining the cold chain

-

Monitoring for chemical and food containers

-

Warning messages in case of deviation from specified temperature limits

Contact us