INTRANAV Global Valuable Shipping

DIGITAL Supply Chain

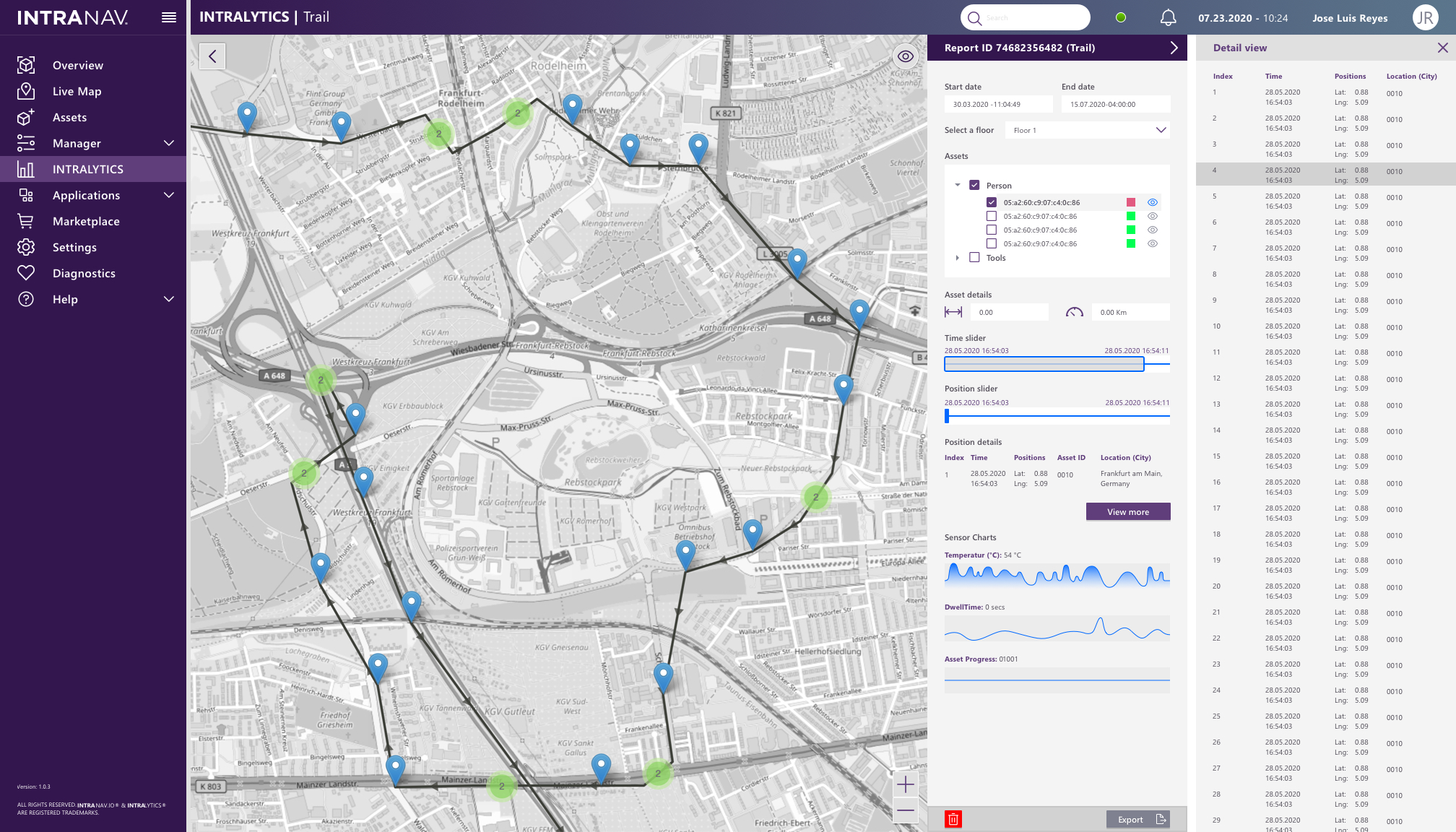

Global track & trace as well as sensor data monitoring

of your load carriers

With INTRANAV you track your load carriers globally in real-time and monitor them with INTRANAV SMART sensors. This allows you to intervene in time in case of deviations in condition during transport (as well as in standing position) and avoid dangerous situations.

DIGITAL Supply Chain monitoring

- Safety box tracking: Lithium-ion batteries

- Theft protection

- INTRANAV Warning system

- Control of transport conditions

-

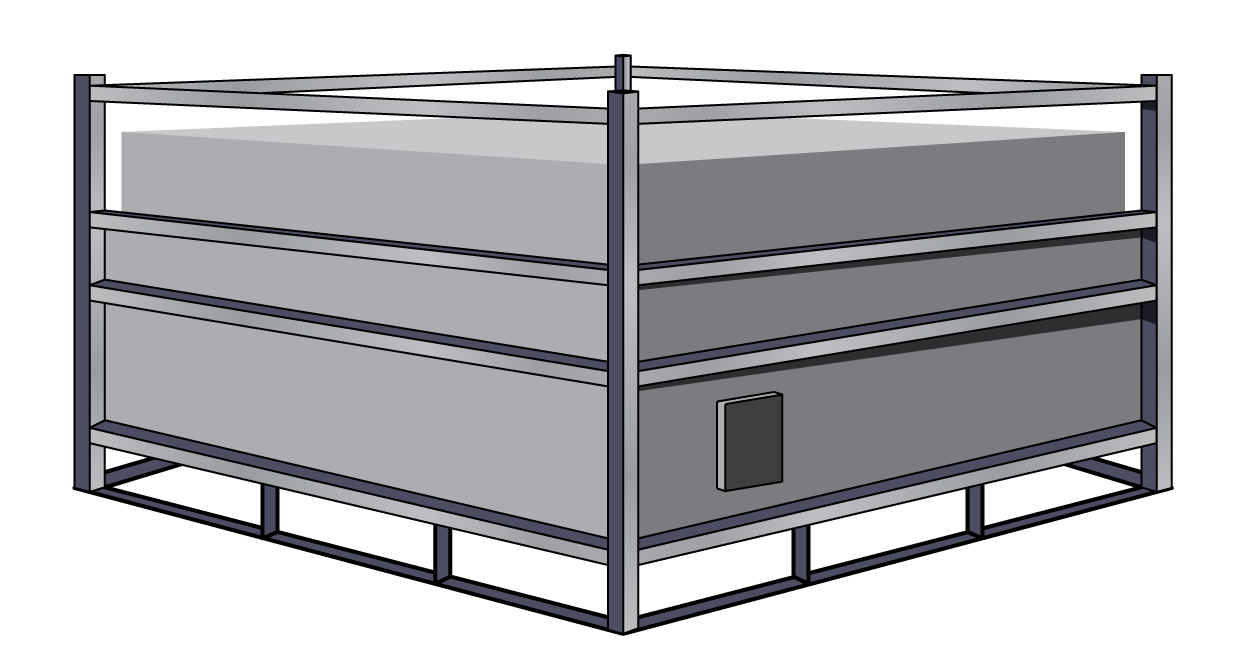

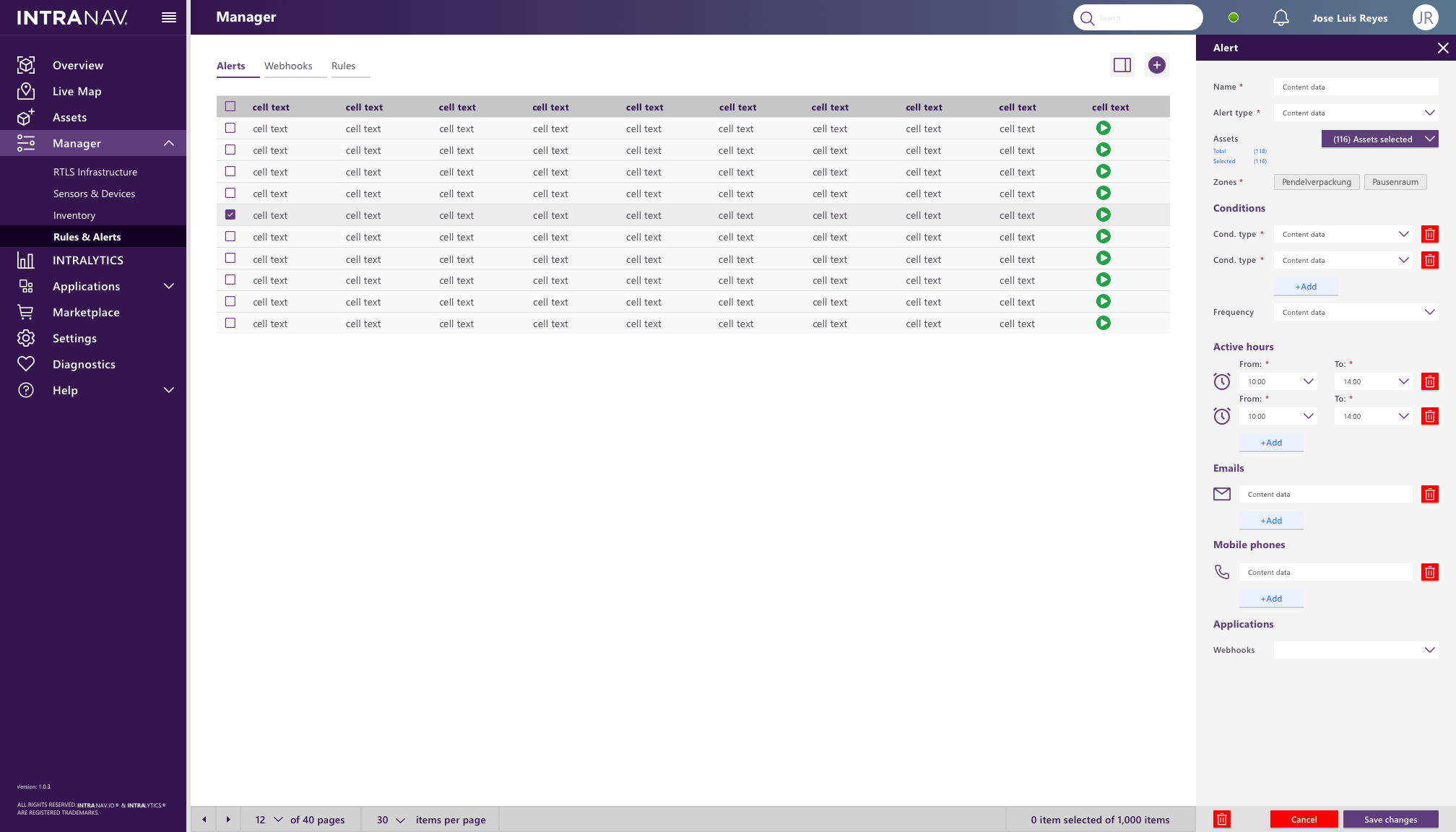

Often safety containers are subject to strict official regulations due to their loading (including lithium-ion batteries) and are therefore declared as hazardous goods. An external temperature sensor can determine values within the container in real-time and increases process safety by permanently monitoring the lithium-ion batteries. The INTRANAV Real-Time Location System supports container management in minimizing the risk of temperature damage that could occur during transport or storage of lithium-ion batteries. If the temperature exceeds the non-critical range for lithium-ion batteries between -40° and 80° during transport, a notification is generated to warn the user if the temperature is exceeded. This notification can be sent via SMS or e-mail to the responsible department.

-

The (safety) containers are made of solid stainless steel and represent a correspondingly high value. That’s why the position determination by our GPS solution not only helps to track and digitize them (Digital Twin), but also serves as theft protection.

-

If defective or damaged lithium-ion batteries are transported, INTRANAV can be used as an early warning system. By monitoring the inside of the container, the thermal reaction of a battery can be detected and reported by a notification. By detecting the chemical reaction, further safety measures can be initiated. E.g. evacuation of hall areas or leaving freeways during transport from escaping hydrofluoric acid. For the protection of employees, the early warning system can be taken much faster.

-

Use INTRANAV Sensor Data Monitoring via the INTRANAV.IO IoT platform to prove in real-time or via reports that transport guidelines such as temperature, humidity, acceleration (vibration) were adhered to, or if there was a deviation. Deliveries with breakage or similar are thus immediately detectable.

INTRANAV real-time & sensor data monitoring features

Plug & play cloud solution

-

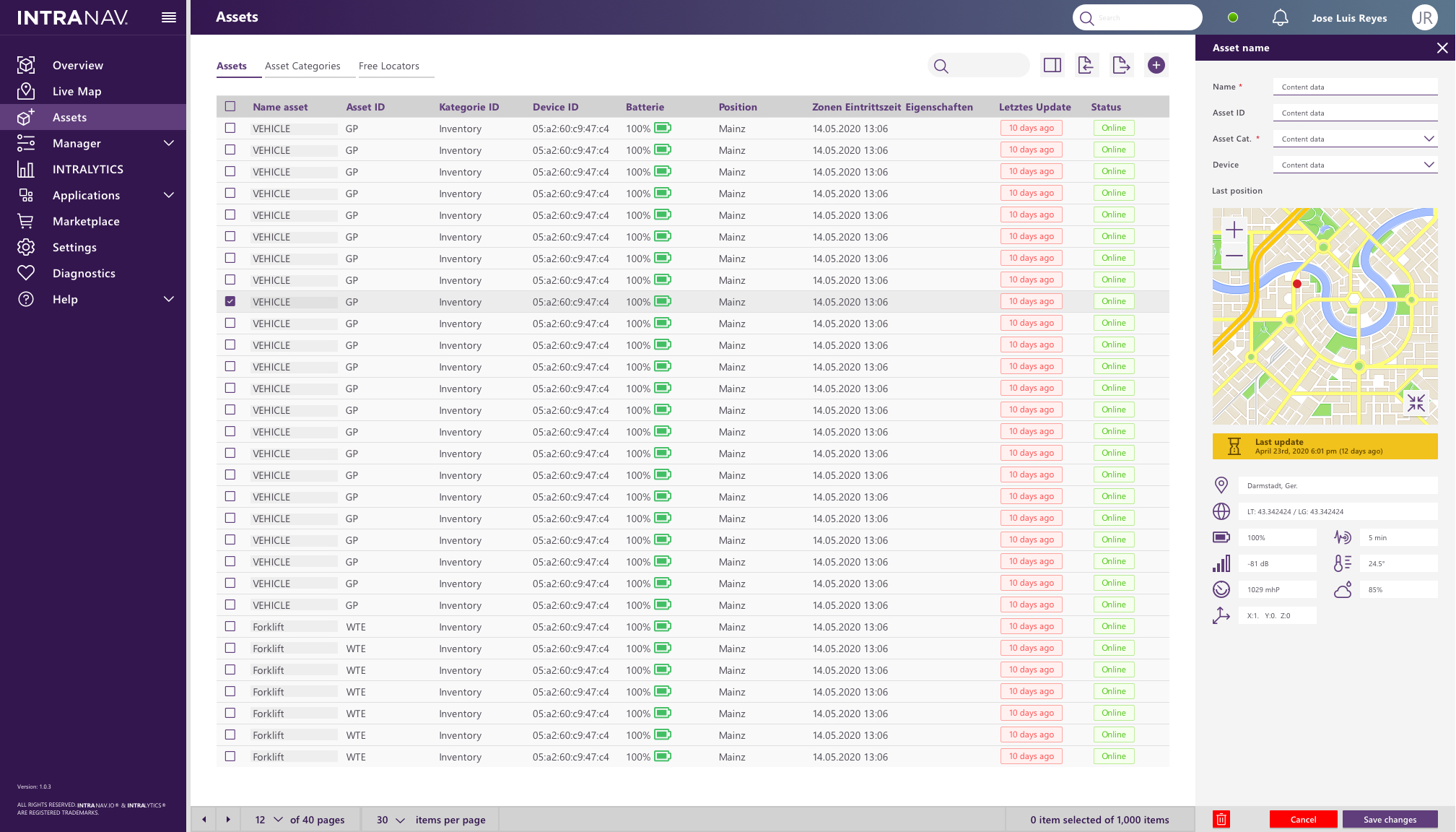

Digital Twin of your load carriers

-

Condition monitoring with

INTRANAV SMART Sensors -

Real-time alerts

-

Hazard monitoring

-

AUTO-ID

-

2D/3D zones and events

-

Storage safety

-

Transport safety

-

App for damage reports

INTRANAV benefits

- Maximum process reliability

- Control of transport conditions

- Theft protection

- Reduce search times

- Reduction of running operational costs through AUTO-ID

- Employee safety through Sensor Data Monitoring

- Proof of compliance with transport conditions

- Automated load carrier management through (virtual) zones – Events

- Coupling to SAP, Analytics, and many other systems (open interface)

It’s that easy!

-

Activate the INTRANAV Plug & Play Solution

-

Install INTRANAV.RTLS TAG (Tracker) at Shipment Box

-

Real-time tracking & sensor data monitoring of your load carriers via the INTRANAV.IO platform

-

Scale INTRANAV Digital Twin Suite as required per device

Discover INTRANAV solutions

-

Sensor Data Monitoring

Read more -

Automatisierung und Prozessoptimierung

Mehr erfahren -

IoT Suite

Mehr erfahren