INTRANAV tool and robotic handling

DIGITAL Solution

Precise 3D localization to avoid errors of

manual and automatic processes in production

The INTRANAV SMART Tool System (STT) is the basis for a new level of flexible location, automation, maintenance, and process assurance in manufacturing. Dynamic, self-organizing production concepts can already be implemented today using real-time location & sensor data monitoring. Robots must know their own position as well as the position of the products to be processed, tools must be able to be found directly and systems must be maintained with foresight. Consumption and capacity analyses are also a prerequisite for efficient production planning. With INTRANAV real-time Location data this is now possible.

[ Download INTRANAV SMART-Tool-Tracking Brochure ]

Real-time tracking & monitoring of movements and status of

your tools, equipment, and robots

- Direct location of your tools via the Digital Twin

- Monitoring & logging of screwdriving processes

- Avoidance of Foreign Object Damage (FOD)

- Shrinkage reduction

- Predictive Maintenance

-

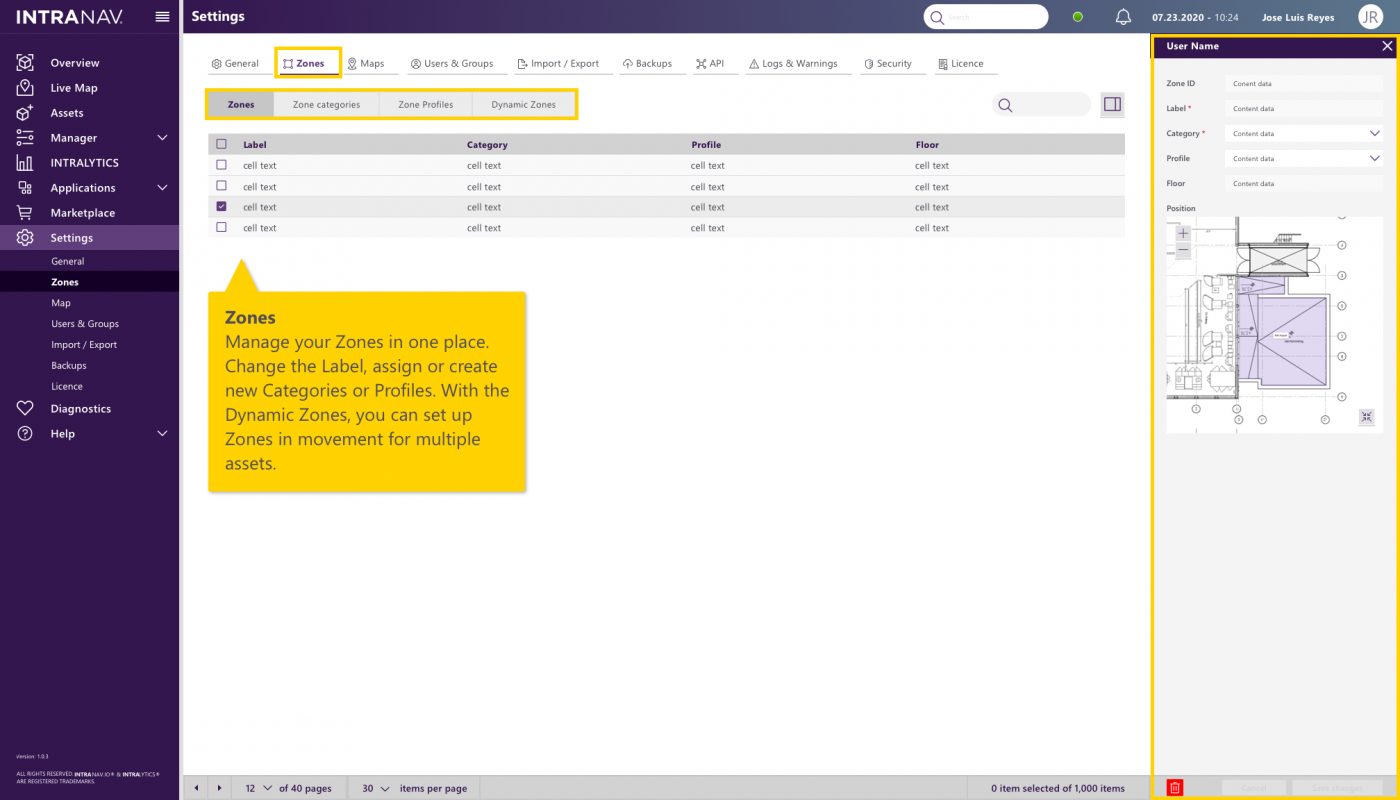

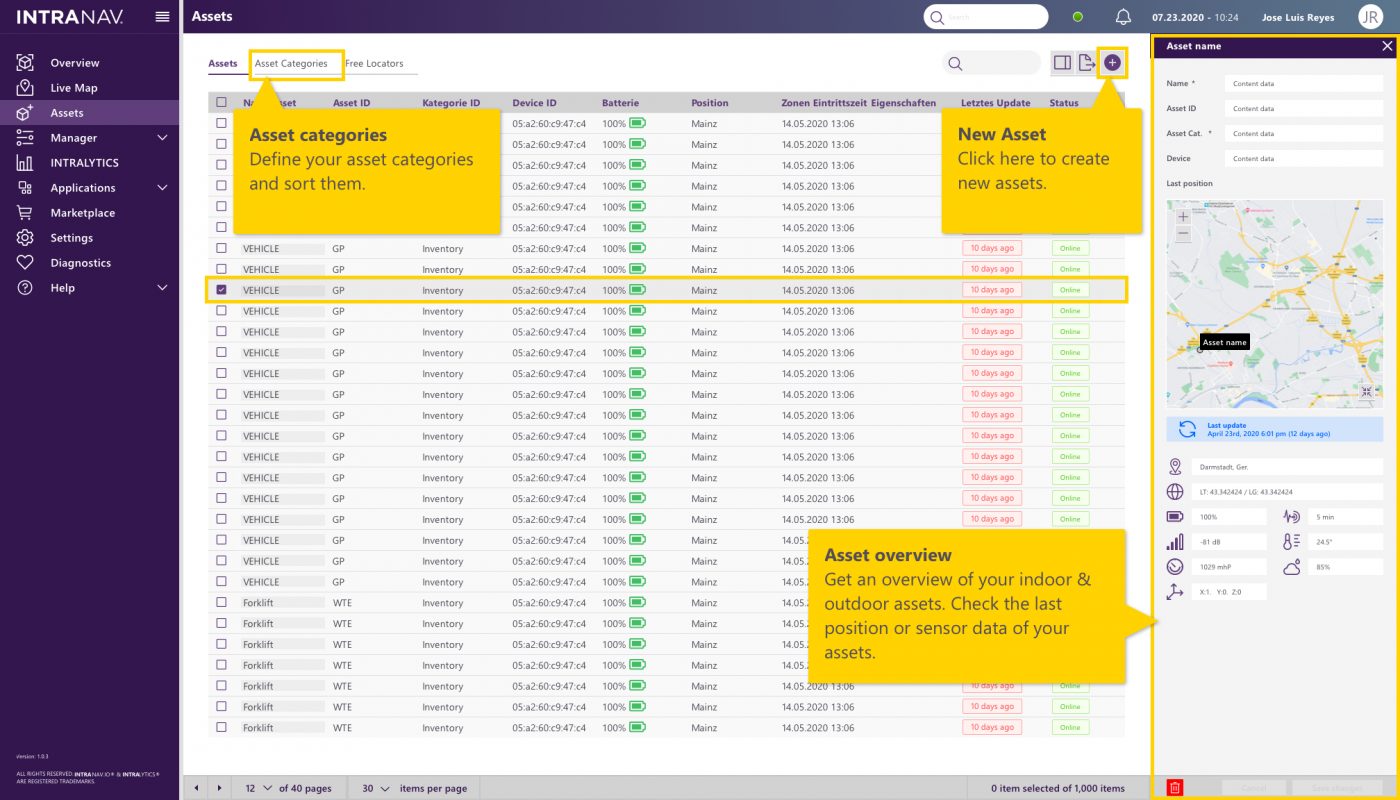

With precise location tracking accuracy of up to ± 10 cm you have a permanent overview of the position of the tool, your entire tool stock on the indoor & outdoor terrain as well as the condition (i.e. pressure, temperature, rotation and movement, humidity, shock, acceleration) of your tool which you can access and monitor with INTRANAV.IO via the Digital Twin Live. Control the entry of prohibited zones, for example, of larger machine tools that may only be operated by machine operators. The optimal use and distribution of tool capacities enables you to achieve a significant increase in productivity. The additional equipment of the INTRANAV.RTLS TAGs with the Pick-by-Light function (TAG lights up on signal request) ensures fast retrieval during manual searches.

-

Track electrically, hydraulically, and pneumatically hand-guided tools in assembly processes with centimeter precision. The integrative solution offers the possibility to digitally log screwdriving processes and to block electric tools (Auto-Blocking) if they are not used at the correct installation point. On the INTRANAV.IO Live Map, virtual zones and distances can be defined as required, for example, to monitor and log screwdriving processes. In addition, the INTRANAV SMART Tool System (STT) can be connected to tool controllers to enable real-time intervention. You always receive the current position and attitude (orientation / tilt angle) of the tool.

-

In aircraft as well as on the store floor, a high level of damage can be caused by FOD (Foreign Object Damage). Therefore, our customer from the aviation sector already uses the INTRANAV STT module in the production of a military transport aircraft. This eliminates the possibility of leaving objects such as tools behind inside the aircraft. The overview of all tools can be followed live on a dashboard. In addition, the module is equipped with a warning system that generates early alarm signals if objects are left behind.

-

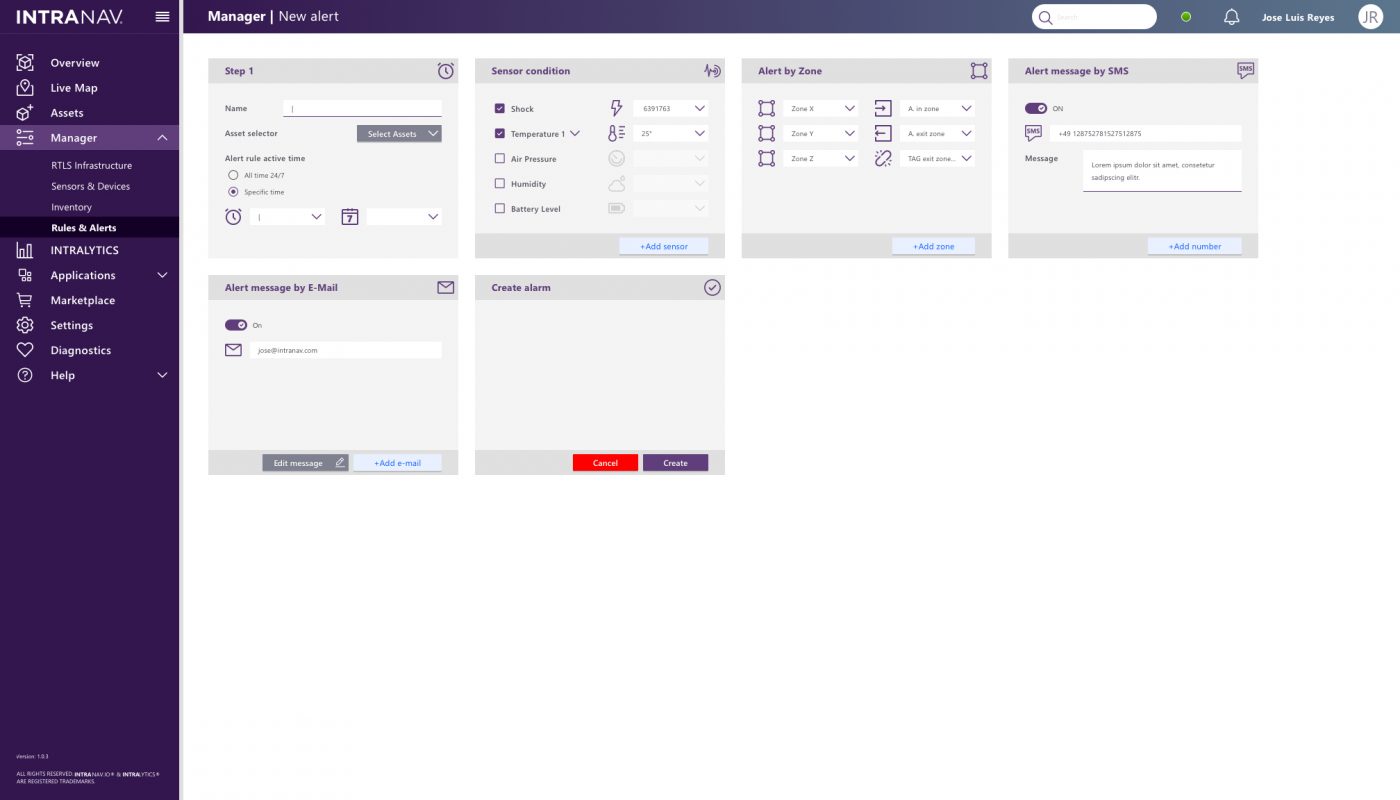

With Real-Time Location Tracking of your tools and robots, you ensure direct traceability through centimeter-precise location information via the INTRANAV.IO Live Map or the INTRANAV.IO Asset Manager. This means you always know where tools that have been accidentally misplaced or stolen are located. Reduce or prevent theft and shrinkage by tracking production equipment and industrial goods. In addition, you can prevent tools from being removed from areas via (virtual) zones by receiving an immediate warning via SMS or email when tools leave the zone. When linked to other systems, doors or gates can be blocked in case of unauthorized removal of tools, for example, so that unauthorized relocation can be ruled out. Coupling to signal or alarm lamps is also possible.

-

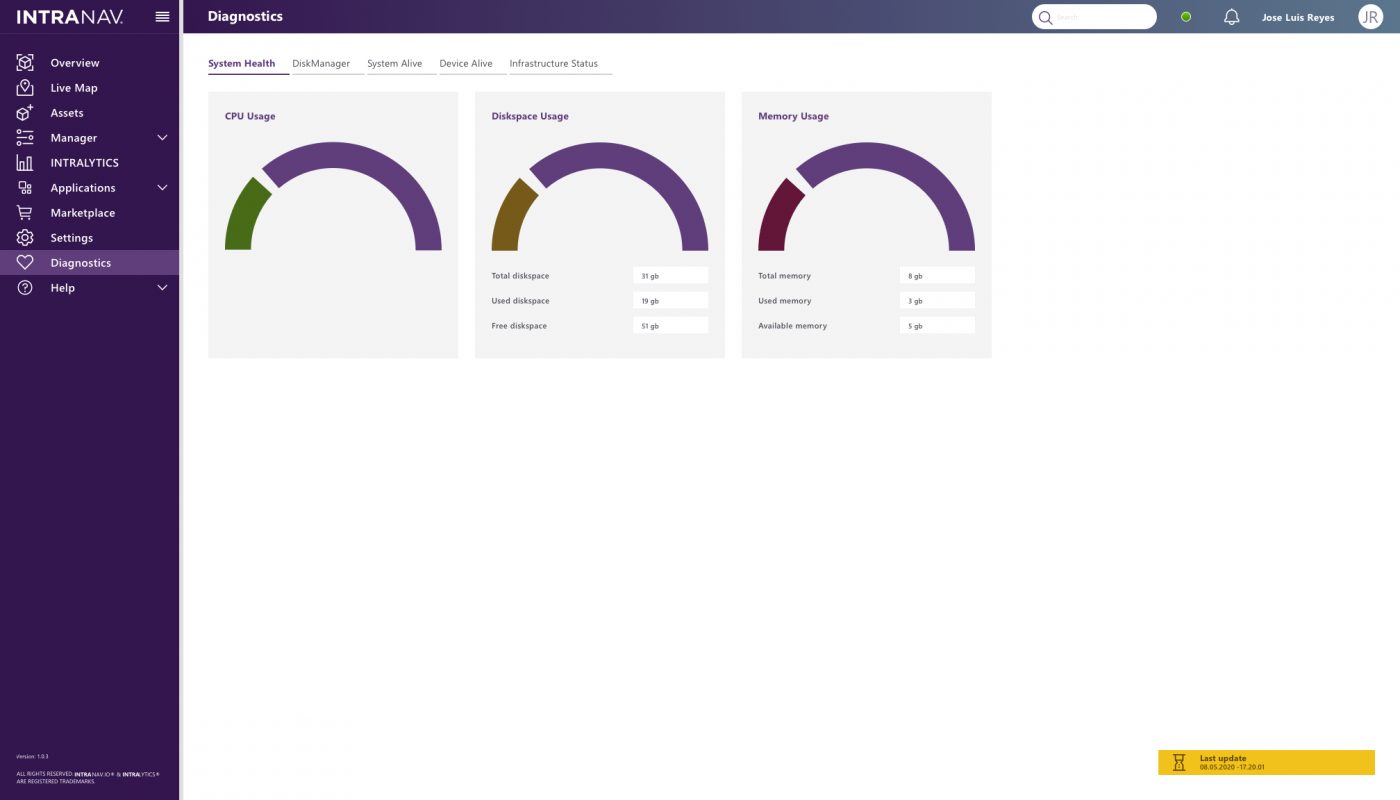

Use INTRANAV to track measurement and production data of your robots, tools, machines, and equipment to obtain automatic maintenance information. This allows you to proactively maintain your tools and equipment, avoid downtime, and minimize production interruptions. In the best case, INTRANAV allows you to predict future tools and robotic maintenance before failures occur. Proactively prevent the actual occurrence of plant and production interruptions.

INTRANAV Tool & Robotic Location Features

Digital RTLS Solution

-

Digital Twin of your

Tools & Robots -

Condition Monitoring with

INTRANAV SMART Sensors -

Real-time alerts

-

Hazard monitoring

-

Auto-Process-Blocking

-

2D/3D Zones and Events

-

Orientation and

position angle

information (R-P-Y) -

Analyses (tool utilization

and much more) -

Pick-by-Light Function for

immediate tool visibility

Your INTRANAV Tool & Robotic Handling Benefits

-

-

- – Optimization of tool & material planning

-

- – Avoidance of FOD (Foreign Object Damage)

-

- – Increase productivity & improve efficiency

-

- – Quick location of tools and equipment

-

- – Elimination of the risk of theft

-

- – Increase of the tool life

-

- – Scheduling for tools

-

- – Historical Logging

-

- – Evaluations and statistics via INTRALYTICS Analysis Tool

-

- – Freely definable virtual zones (geofences)

-

- – 100% transparency about location and condition of tools & robots

-

- – Easy integration and coupling into higher-level systems (coupling to SAP, Analytics and many other systems through open interface)

-

It’s that simple!

-

Activate the INTRANAV Plug & Play Solution

-

Attach INTRANAV.RTLS TAG (tracker) to tools or robots

-

Real-time Tracking & Sensor Data Monitoring of your tools or robots via the INTRANAV.IO platform

-

Scale INTRANAV Digital Twin Suite as desired per device