INTRANAV Showroom at the MHPLab

in Ludwigsburg

INTRANAV Live Showcase

Enabling you to shape the future!

MHP Management- und IT-Beratung GmbH is a globally active and leading management and IT consultancy and develops pioneering mobility and manufacturing solutions for international corporations, established medium-sized companies, and disruptive start-ups. With over 3,000 employees, MHP is driving digital progress at 20 locations worldwide – together with over 300 customers.

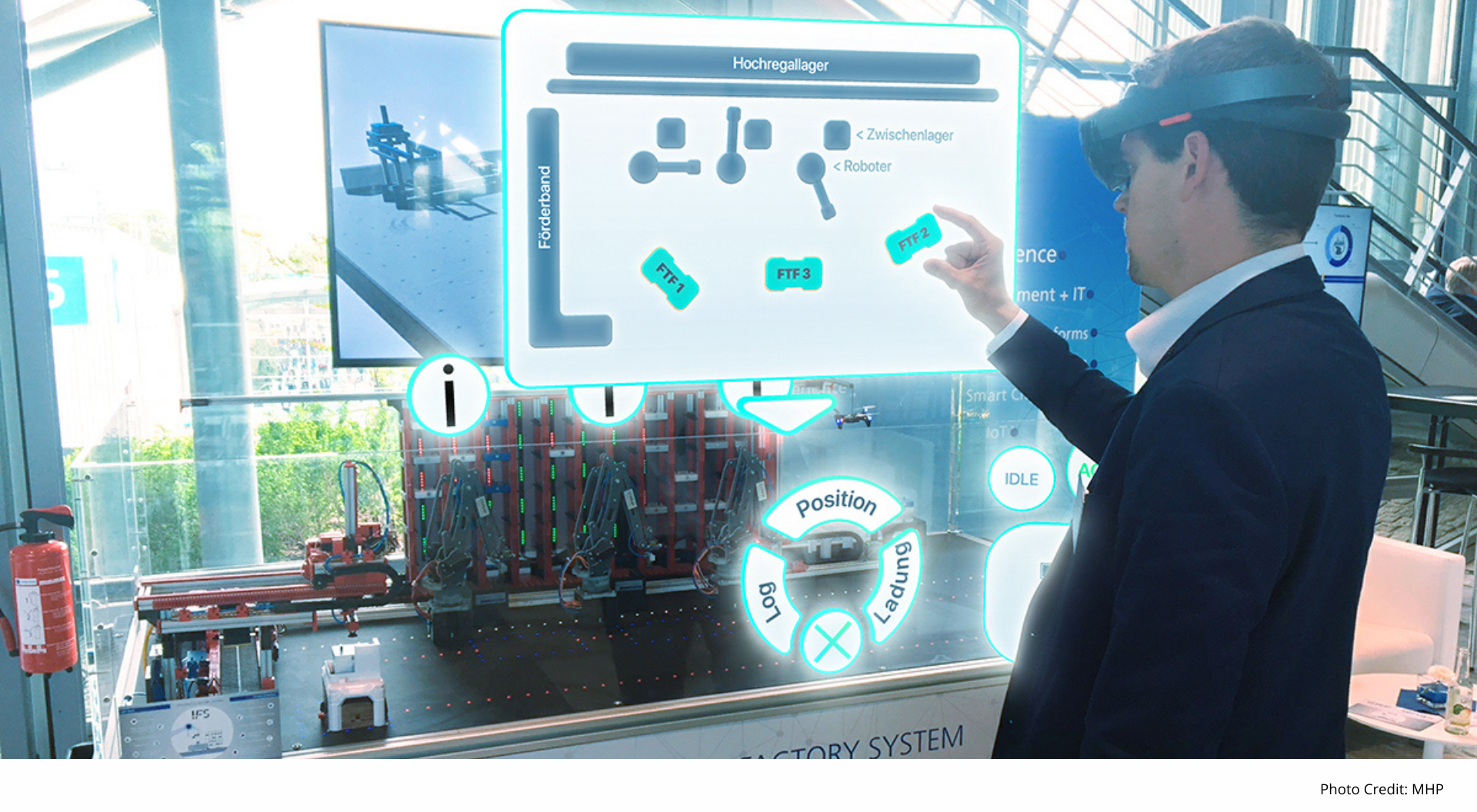

As an IT consulting industry expert, MHP, as a subsidiary of Porsche AG, offers its customers the opportunity to develop ideas independently and to design and build prototypes in the MHPLab in Ludwigsburg. Here, it is possible to test on site how digital use cases of the Smart City and Future Mobility function. MHP’s “Lab as a Service” offer is aimed at established companies as well as innovative start-ups; the focus of the Lab is on the further development of artificial intelligence and Internet of Things (IoT) business models and solutions.

Part of the Lab is the so-called “Integrated Factory System” (IFS), where a real simulation of a production store floor with three stations including robots and autonomous guided vehicles is presented. Here, solutions from the real production environment can be designed and tested with intelligent sensors and AI-based visual inspections, among others.

We at INTRANAV are very pleased to be present at MHPLab with our independent RTLS IIoT suite and to work together on topics such as collision avoidance for AGVs as well as for manual transport vehicles for use in the near future.

Industry 4.0 Use Case Testing at MHPLab: Transport Flow Management with the INTRANAV RTLS IoT Suite

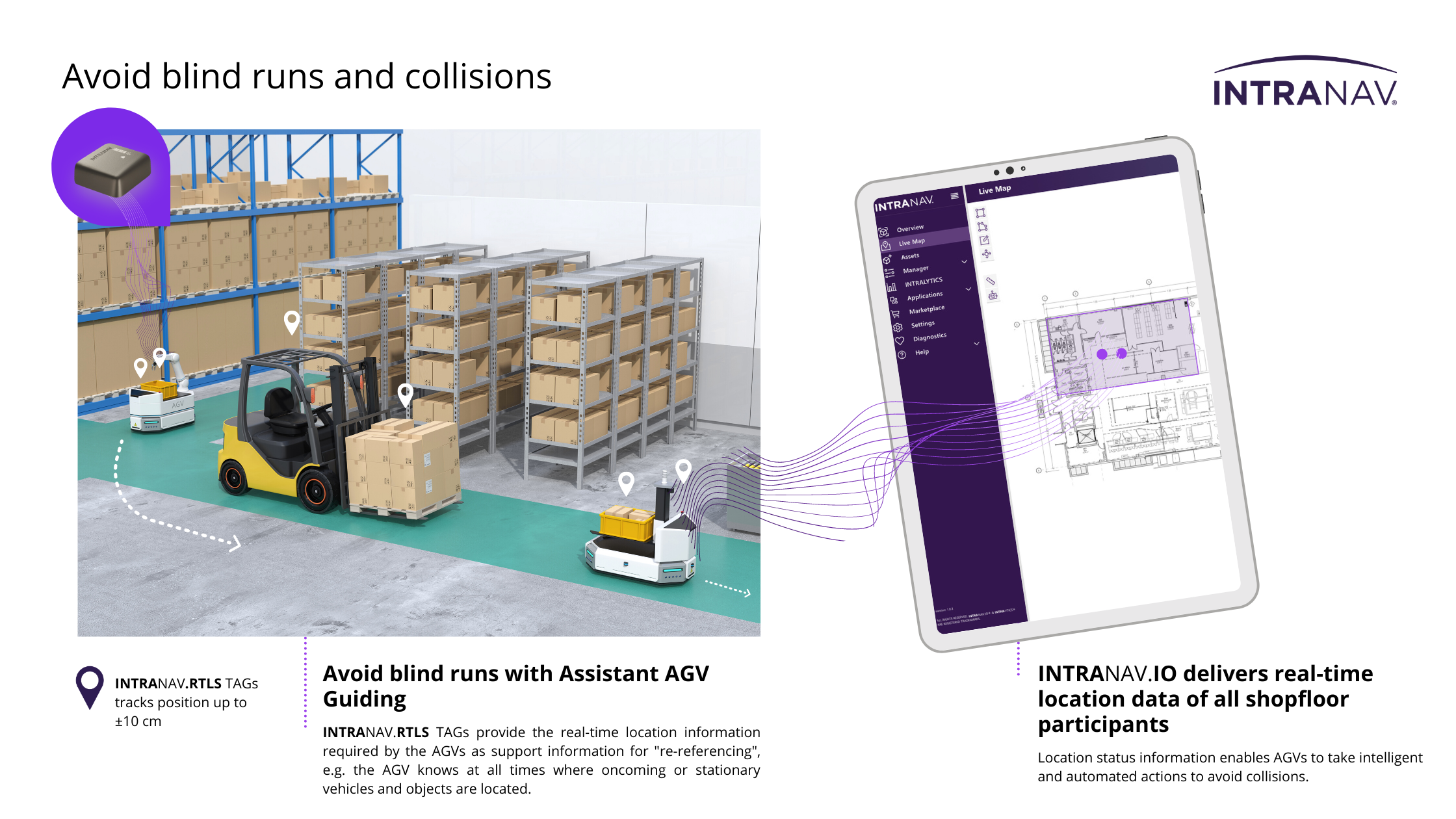

- Transport testing & real-time location monitoring of forklifts & AGVs

- Collision avoidance of mixed fleets via INTRANAV.IO

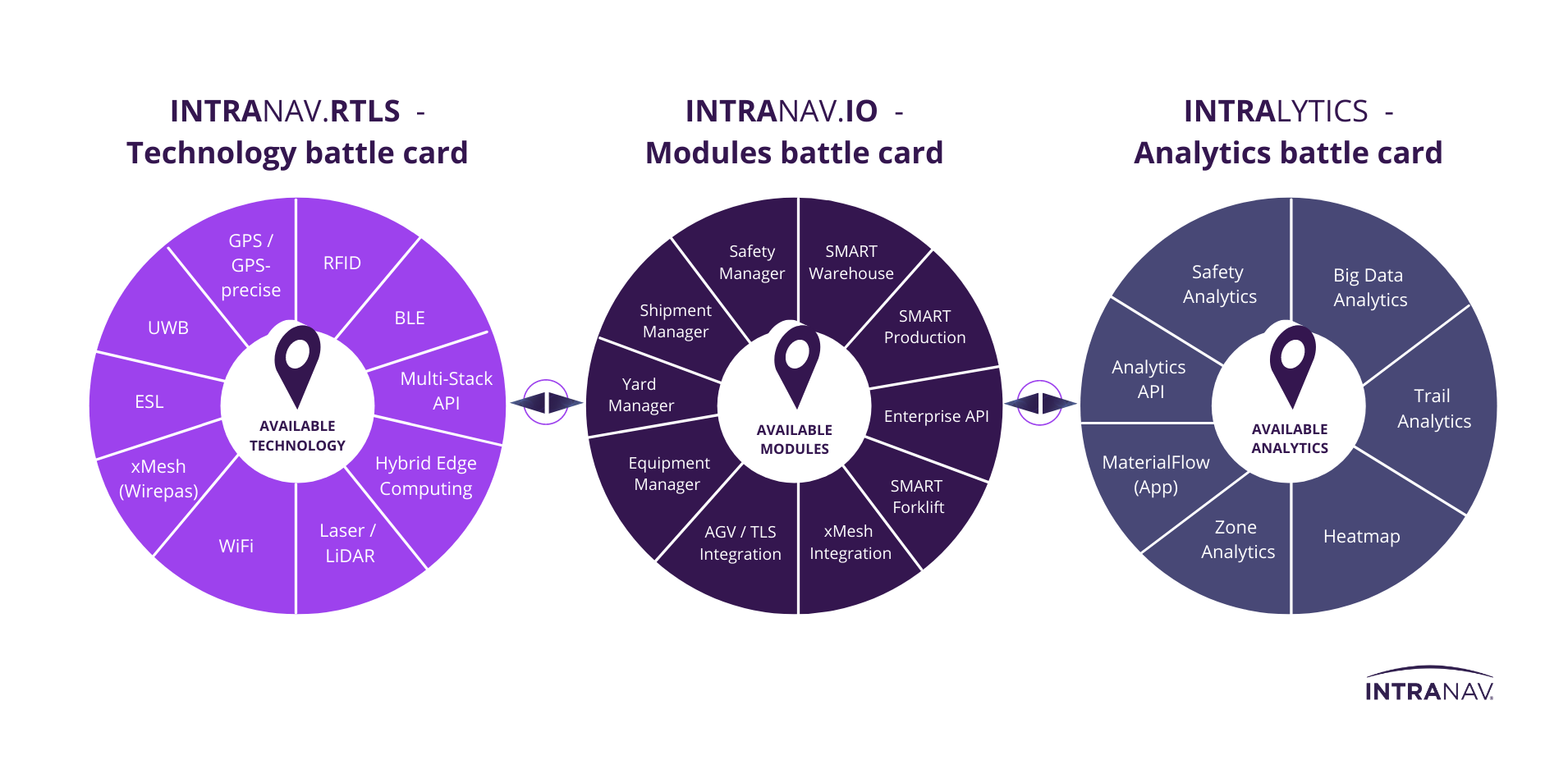

- Industry 4.0: When are which tracking technologies useful?

- Fundament of the RTLS infrastructure: Ultra-wideband RTLS.NODE

-

The MHP Integrated Factory System, which is equipped with three production stations, is located on the 140 square meter test store floor of the MHPLab. Connected to this is a high-bay warehouse with an automated Storage & Retrieval System (ASRS). Physically, the stations are connected by Automated Guided Vehicles (AGV/FTS) and a forklift, which fulfill delivery and pick-up orders. Factory processes are linked to a corresponding SAP system.

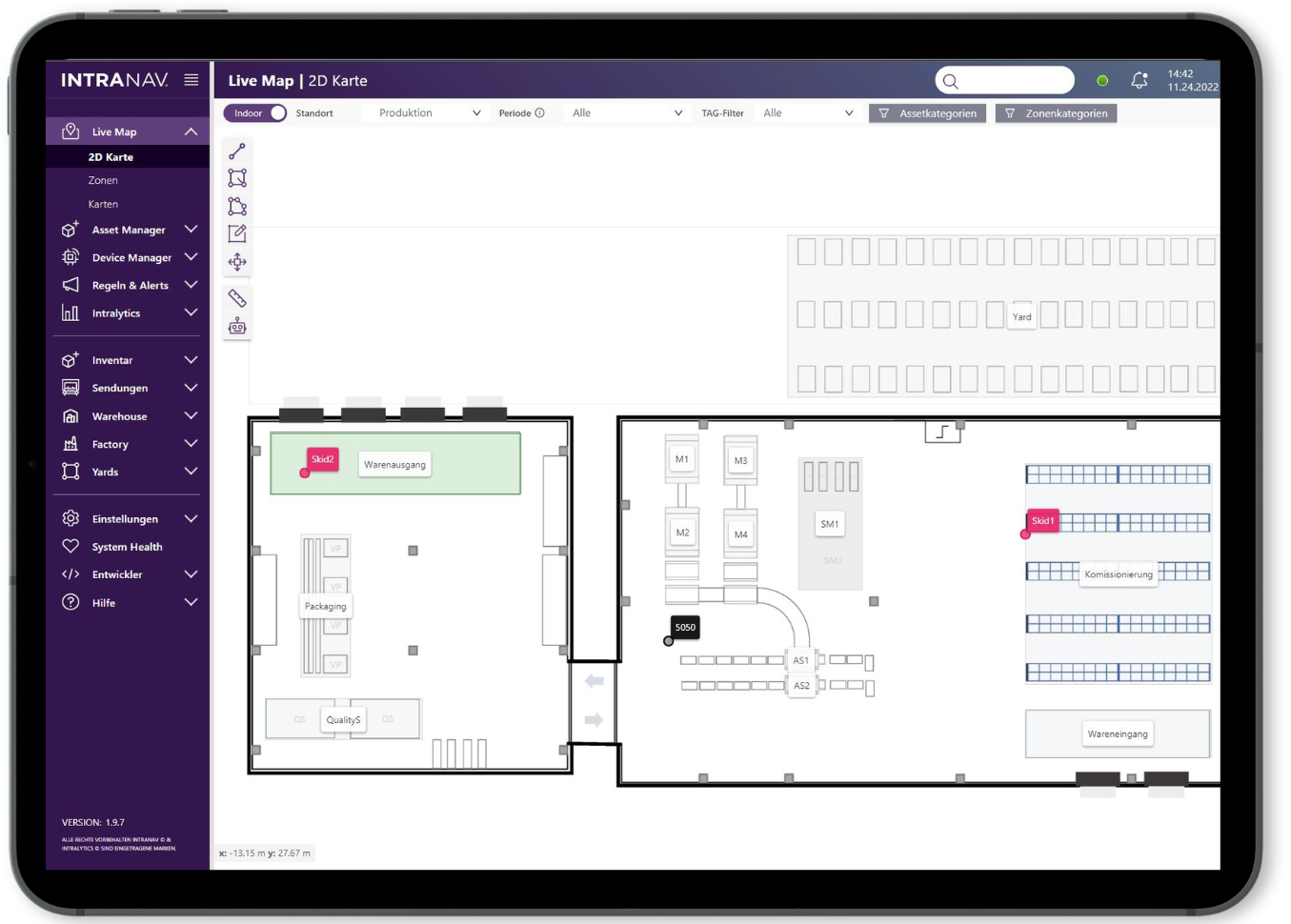

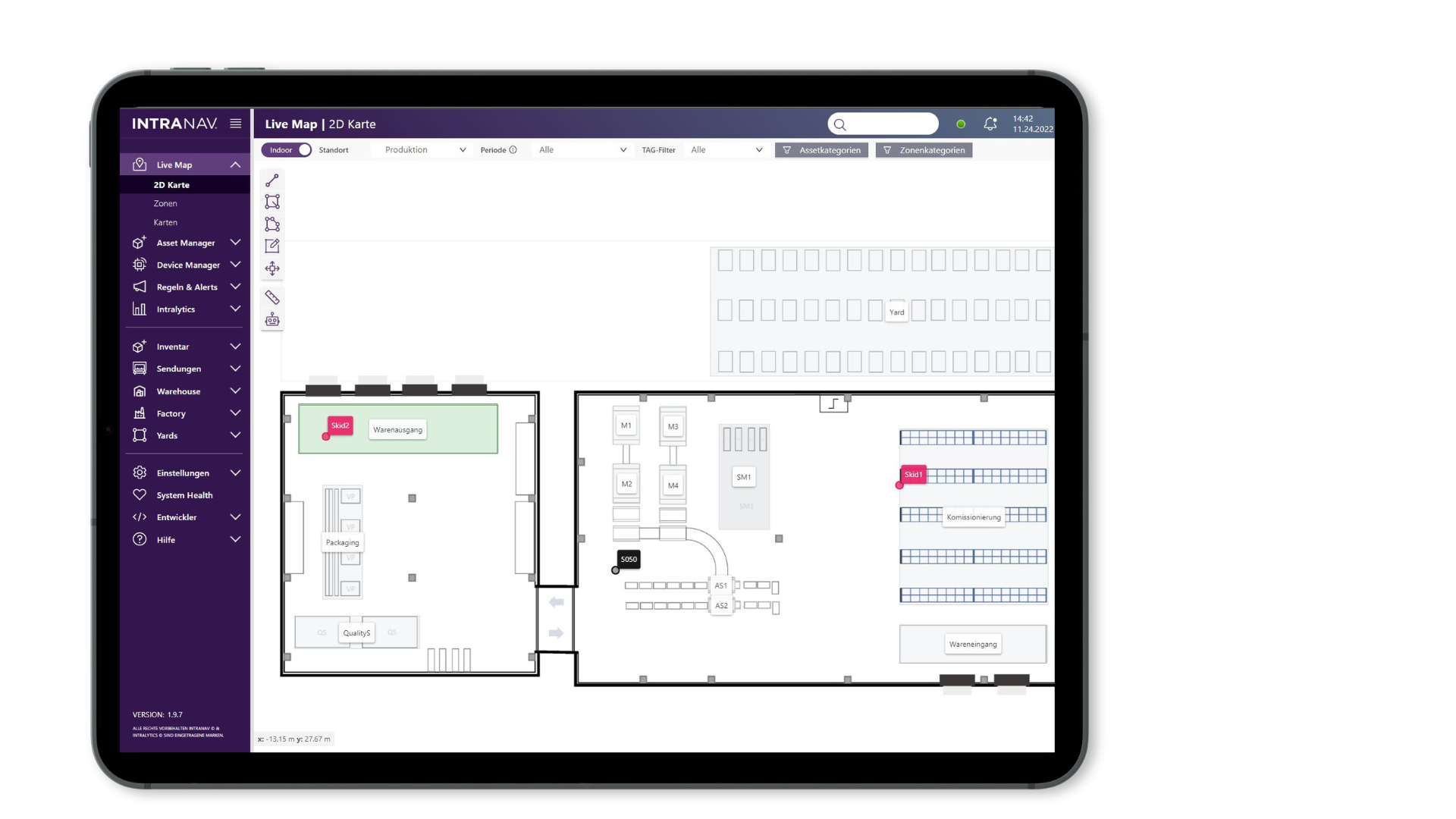

The installed INTRANAV.RTLS TAGs track the respective transport process steps of the vehicles in real time and visualize the movements and transport orders via real-time location data using the INTRANAV.IO Digital Twin platform on the MHPLab Floorplan. Through transport store floor monitoring, INTRANAV.IO examines how the vehicles move on the store floor or in which cases there are latency times and how high these actually are.

This production simulation is used to analyze and test a wide variety of logistics, production and supply chain scenarios.

-

MHP and INTRANAV are currently working on collision avoidance for manual and automated guided vehicles (AGV/FTS) and mixed fleet coordination. Exchange ideas about INTRANAV Intelligent AGV Management – SMART Warehouse Solutions on site.

-

Let us explain you the advantages of precise real-time tracking compared to Bluetooth or WiFi based solutions. Learn for which supply chain applications mesh technologies make more sense (e.g. inventory management) and how you can control and manage assets & vehicles across locations within the supply chain with INTRANAV.IO.

Test the high positioning accuracy (± 10 cm) of our ultra-wideband based INTRANAV.RTLS technology in the MHPLab by simulating different use cases yourself.

-

The full scope of our real-time location system also includes the INTRANAV.RTLS NODE, which is part of the tracking infrastructure. It receives the signals from the TAGs and ensures the flawless backend calculation of the positions to be tracked. These are easily scalable and practically maintenance-free.

-

Create scalable added value

with the IoT RTLS Platform Suite

-

100% Digital Twin Digital Shadow

The foundation for process digitization, automation & optimization of industrial workflows, equipped with IoT RTLS features such as event engine for geo-fences and virtual zones.

-

Digital Supply Chain

End-2-End Tracking and Control-Tower for flexible and precise tracking (indoor ±10cm and global with our INTRANAV.GPS TAGs) of vehicles, goods, tools, load carriers.

-

Process-Flow Live Reports

Real-time data analysis tool for the optimal material flow (trail, zone, heat map, material flow, etc.) as well as connection to third-party providers with the ability to visualize unlimited analysis dashboards.

Test and design key technologies for

smart city & future mobility.

MHP Management- und IT-Beratung GmbH

Königsallee 49

71638 Ludwigsburg

Germany