20.01.2022

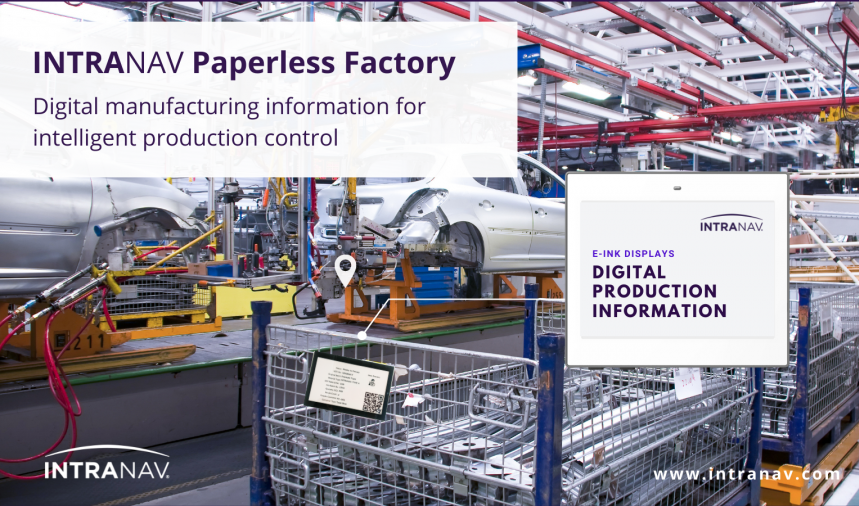

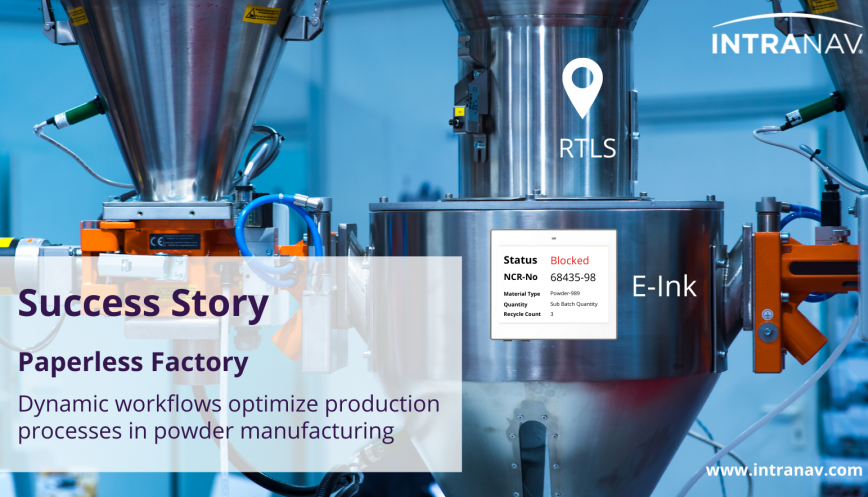

How can E-Ink displays and INTRANAV.RTLS be used to establish the benefits of digitization in your organization?

The paperless factory offers great savings potential by reducing paper, labels, printing devices and emissions. With the INTRANAV.IO platform, E-Ink displays can be used efficiently in manufacturing and logistics processes. In connection with SAP systems, barcode / QR code, parts lists and assembly information can be imported directly to the display via INTRANAV.IO to dynamically control intralogistics and assembly processes.